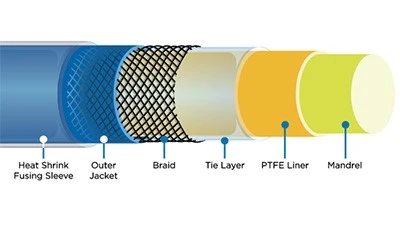

Orangeburg, South Carolina – Zeus Industrial Products Inc. launched its latest polymer solution for medical device manufacturers. Tie Layer is an ultra-thin thermoplastic coating applied over a catheter liner during catheter construction. The coating creates a melt-bondable substrate that improves adhesion to both the liner and the catheter jacket during the reflow process.

Zeus developed Tie Layer to reduce delamination between materials that are otherwise not melt-compatible for bonding. Delamination is a challenging failure mode in catheter construction and carries both risk and cost burden for many device manufacturers. Detection typically occurs during final testing, after production of the complete catheter assembly, resulting in significant final product yield loss.

More importantly, delamination can lead to failures in the field and product recalls. By creating a stronger bond between the outer catheter jacket and inner liner, Zeus’ Tie Layer solution enhances and increases consistency in catheter performance and ultimately improves patient safety. Also, it reduces inspection requirements, increases product yield, and lowers manufacturing costs. Reduced cost and improved performance make Tie Layer a true total solution in catheter design and manufacturing.

Zeus’ Tie Layer solution follows on the heels of another recent innovation. The company’s new FEP 2:1 heat shrink offers a pure FEP heat shrink in a ratio larger than current 1.3:1 or 1.6:1 options. The expanded capability of this Class VI approved product minimizes the need for manual stretching and makes covering uneven and angular surfaces easier, faster, and more reliable.

Zeus is showcasing both new solutions at Medical Design & Manufacturing (MD&M) West, Feb. 5-7, 2019 in booth #3113.