Today’s medical endoscopic and ophthalmic catheters are subjected to dozens if not hundreds of manipulations in any given procedure. These manipulations bend the fiber optic lighting cables creating stresses that can ultimately lead to diminished or loss of light failures. To combat the costly requirements of repair or replacement, Toray improved its Raytela plastic optic fiber’s bend resilience and validated it through stringent testing.

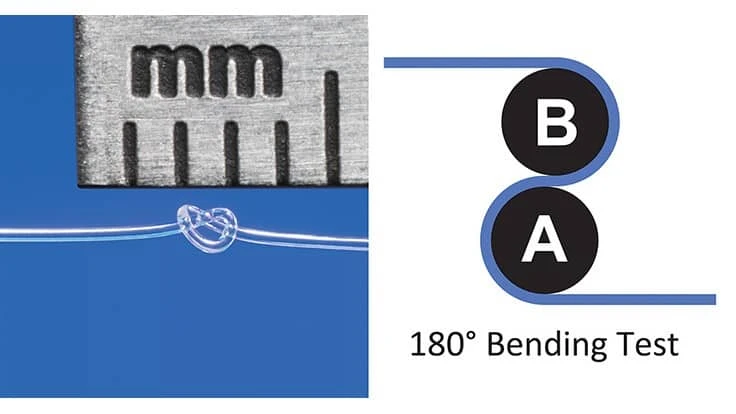

Toray Raytela plastic optic fiber has been extensively tested in a tightly controlled, 77oF environment deploying a 2-point bending test comprised of 10mm diameter stainless steel rods and 175 gram weighted pulls on both ends of the fiber. Using a 1m sample length fiber, the automated testing machine conducted a series of repetitive bending tests of full 180° bends. The test series of numerous Toray Raytela plastic optic fiber cables resulted in a measured average of 34,500 bends before breakage, a significant accomplishment and a durability feature to be welcomed in the Medical design community for Endoscopy Illumination and Ophthalmic Lighting Equipment.

Raytela plastic optic fiber is a proprietary design constructed with an outside fluorinated polymer cladding and internal core of polymethyl methacrylate developed by Toray industries. The unique construction of cladding and core increases the overall fibers strength of Raytela and increases its resistance to surface damage, providing the capability to withstand long-term, in-service use with proficiency to negotiate repetitive bending and in surgical devices.

Raytela is a high numerical aperture optical fiber for medical applications with additional design features achieved by its cladding and core design construction including being more reflective and able to transmit and reflect light at a large, 79° angle through the core. This unique feature provides less light loss at all bend radius and up to 1.8x wider light broadcasting at the distal end. Raytela fiber can negotiate tight 9mm radius bends and easily bend back upon itself 180° while continuing to provide effective lighting in smaller devices for clear navigation.

Toray uses full length automated camera inspection for Raytela, ensuring zero contamination. The manufacturing process for Raytela is consistent and in accordance with its FDA Device Master File, MAF3188.Toray’s additional corporate commitment to “No Change Production Methods”, “No Change Formulations” and “No Change Test Methods/Equipment” ensures long term stability to meet regulatory requirements and provide confidence to manufacturers.