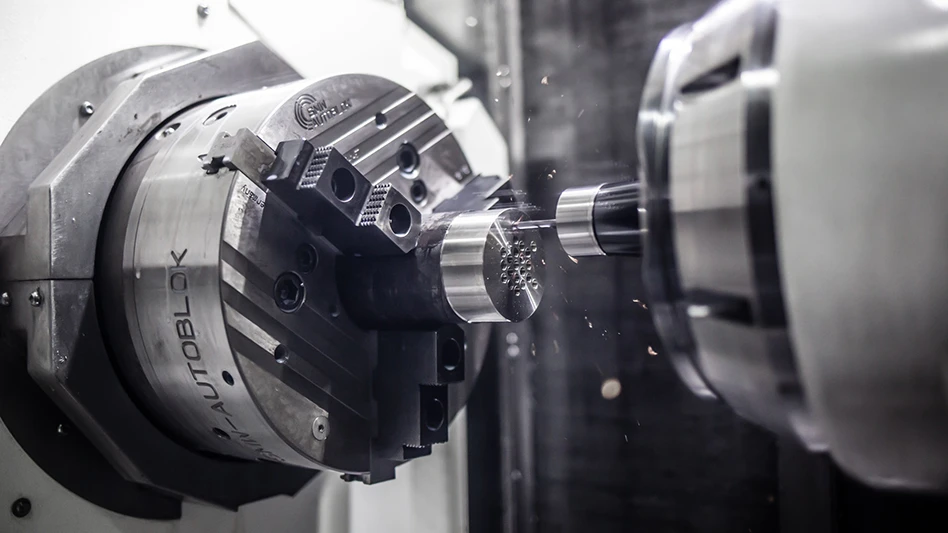

CREDIT: SWISS STEEL GROUP

Swiss Steel Group presents UGIMA-X, the third generation of high-machinability stainless steels, delivering significant advancements in machining efficiency, tool life, and process reproducibility. This evolution results from over three decades of application-oriented research and close collaboration with industrial partners.

The latest generation introduces three specifically optimized grades:

UGIMA-X 4021, a martensitic stainless steel designed for demanding mechanical applications or food and beverage applications requiring high strength.

UGIMA-X 4028, a martensitic stainless steel offering enhanced mechanical resistance, food and beverage compatible for precision components.

UGIMA-X 4460, a duplex stainless steel that combines excellent mechanical properties with outstanding resistance to corrosive environments and at the same time, easy to machine

These newly developed steels provide an average 20% increase in productivity, 25% to 50% longer tool life, improved chip breakability, and exceptional reproducibility across production batches.

Innovative metallurgical optimization for maximum efficiency

The development of UGIMA-X is based on precise modifications of non-metallic inclusions, particularly through the targeted introduction of oxides during the melting process. This refinement enhances chip formation, reduces tool wear, and ensures exceptional consistency in machining properties across different heats.

A critical advantage of this new generation is the significant reduction of quality variations, which have traditionally been a challenge in stainless steel machining. Extensive scientific studies, conducted both at Ugitech’s research laboratory and through real-world industrial trials, confirm the consistent performance of UGIMA-X.

Application-specific benefits for diverse industrial needs

Developed over a three-year period, involving the production of 2,000 tons of material and 3,000 hours of testing, UGIMA-X has been specifically tailored to address key industry challenges:

UGIMA-X 4021 is a martensitic stainless steel in the quenched and tempered (QT) condition, combining high mechanical strength with good corrosion resistance in moderately aggressive, non-chloride environments. It exhibits excellent oxidation resistance up to 600°C. The UGIMA-X process has enhanced its machinability by 28% compared to UGI 4021 and 14% compared to UGIMA 4021, while reducing batch-to-batch variability. This grade is particularly suited for high-stress mechanical components in the automotive and mechanical engineering industries. It is also food and beverages compatible.

UGIMA-X 4028 shares similar characteristics but offers further improved mechanical resistance. With enhanced mechanical resistance and increased dimensional stability, this grade is ideal for high-precision components used in environments requiring moderate corrosion resistance. Machinability has improved by 12% over UGI 4028 and 7% over UGIMA 4028. This steel is particularly well-suited for precision mechanical engineering applications, as well as critical components in the food and medical industries.

UGIMA-X 4460 represents the latest evolution of austenitic-ferritic duplex stainless steel, offering exceptional mechanical strength and outstanding corrosion resistance. By refining the micro-structure with a fine distribution of non-metallic inclusions, productivity gains of 20% to 30% over standard 1.4460 grades have been achieved. Furthermore, UGIMA-X 4460 outperforms conventional austenitic steels such as 1.4404 / AISI 316L, particularly in chip fragmentation and machining stability. Thanks to its high resistance to aggressive environments, this grade is ideally suited for applications in chemical processing mechanical industries.

Long-term cost efficiency through extended tool life

A major benefit of the new UGIMA-X grades is their significantly extended tool life – up to 50% longer than conventional grades. The optimized material composition and controlled chip formation reduce tool damage caused by chip hammering. This reduces machine downtime, extends tool change intervals, and contributes significantly to cost reduction.

In addition to increased tool life, UGIMA-X provides high reproducibility of machining performance, reducing quality deviations across production batches. This results in greater process reliability, improved planning accuracy, and reduced scrap rates.

Technical support and application expertise

The continuous advancement of the UGIMA product family is driven by the company’s close collaboration with industrial partners. For over 30 years, Swiss Steel Group has been providing application-oriented consulting and technical expertise, ensuring that customers achieve optimal results. In addition to supplying comprehensive material data and machining guidelines, Swiss Steel Group offers in-depth analyses of existing production processes to identify and implement optimization potential.

“The launch of 3 new products, completing the UGIMA-X range, is a major step in our offering of unrivalled high machinability grades.

UGIMA-X is the result of several years of intensive research and several thousand hours of testing, which we carried out in close cooperation with our customers," explains Sandra Chedal-Anglay, CSO of the Swiss Steel Group. "Our goal was to increase machinability by up to 20%, extend tool life by 25-50% and ensure even higher batch-to-batch reproducibility. With UGIMA-X, we are setting new standards in stainless steel machining and offering a solution that combines sustainability efficiency, reliability, and cost-effectiveness."

A sustainable material solution with the green steel option

The UGIMA-X grades are not only technologically advanced but also aligned with sustainable production strategies. Swiss Steel Group offers UGIMA-X in an environmentally friendly Climate+ version, produced exclusively using electricity from renewable sources such as wind, solar, and hydropower.

By integrating Green Steel, carbon emissions in stainless steel manufacturing can be reduced. This sustainable alternative enables companies to meet their environmental goals while benefiting from a high-performance material solution.

Redefining performance in stainless steel machining

In summary, the third generation of UGIMA-X establishes new benchmarks in stainless steel machining. These three specifically optimized grades – UGIMA-X 4021, UGIMA-X 4028, and UGIMA-X 4460, extend the range of UGIMA-X already available – Swiss Steel Group provides tailored solutions for a wide range of industrial challenges.

The significant increase in productivity, extended tool life, and outstanding reproducibility makes these materials the preferred choice for high-performance machining applications.