Amorphology, a NASA spinoff company founded from technology developed at the Jet Propulsion Laboratory (JPL) and the California Institute of Technology, is a leader in applying advanced materials and manufacturing technologies toward improving gear production for medical, robotics, and other industrial applications using amorphous metals, also known as bulk metal glass (BMG).

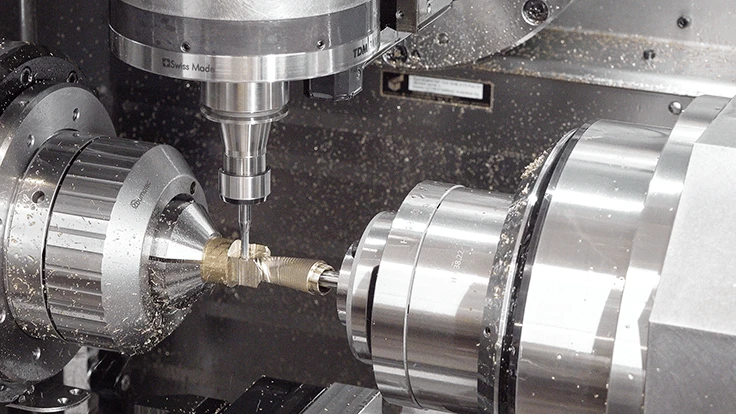

The laboratory will be at Amorphology’s Pasadena, California, headquarters where Starrag Bumotec’s s191H CNC machine will be showcased, machining a wide variety of parts, from mold inserts to rapid prototype gears as well as other production BMGs and traditional metal parts.

“We are targeting high-precision parts with tolerances often <5μm on certain dimensions,” says Jason Riley, Amorphology’s chief operating officer. “The majority of our work is focused on rapid prototyping and production quantities in the hundreds of parts per month.”

Advanced features of amorphous metals

BMGs have several material advantages over traditional steel, titanium and aluminum metals and alloys. Amorphology’s patent portfolio includes several patents focused on high-precision gears for space and other extreme cold temperature applications. Amorphous metals are a non-crystalline class of alloys that cut and chip differently than other materials.

“The Bumotec s191H provides mill-turn capabilities as well as a higher production capacity,” Riley says. “Bumotec can take our alloys and machine single pieces. Or instead of machining one part at a time, it can produce hundreds of pieces lights out.”

Besides making gears for aerospace, Amorphology’s gears are made for use in cobots, robots, and medical devices. For example, most cobots use strainwave gears – the main component being a flexspline. It’s complex, thin-walled and fulfills an important role – to precisely move the arm of the robot.

Many of the cobot, robot, and medical device parts can be cast or injected molded, but at times the micro-parts need to be post-processed to extremely high tolerances.

“Bumotec cut its teeth in designing machines for the Swiss watch industry,” says Greg Dunkley, Starrag Bumotec vice president of precision engineering. “Bumotec has a talent for machining micro-size high-value gears.”

The Bumotec s191H blends Swiss mechanics and state-of-the-art axis drive technologies. The cast iron three-point machine base and linear drives eliminate vibration which yields superior surface finishes. Advanced kinematics and thermal management allow the implementation of numerous high speed machining operations in a small footprint.

Other key features include:

- Linear driven motors and direct-driven rotation axis

- Extensive features with a maximum of 7 axes and 3 spindles

- Unique spindle with high torque

- Universal bar machining (bar passage: 32mm, 50mm, or 65mm)

- Large tool changer for 90 HSK40 tools

- High thermal stability, simple clamping, high finish quality

- Automatic in/out loading unit for blanks

- From bar to finished part, in one single production cycle

- Multiple processes (turning, milling, grinding, drilling, gear hobbing)

- A multi-task machine fully equipped instead of multiple production units

Riley believes the Bumotec s191H will make Amorphology’s own micro gearboxes without lubrication in robots and medical devices. “We will be machining our patented alloys to very small sizes where production quantities don’t require our injection molding process,” he says.

Now it’s your turn to see the Bumotec s191H in action in Starrag’s West Coast laboratory at Amorphology.

For a demonstration, email Stephen Ceplenski: stephen@amorphology.com or Greg Dunkley: greg.dunkley@starrag.com. Or call Amorphology: 213.377.5440, x5, or Starrag: 859.534.5201