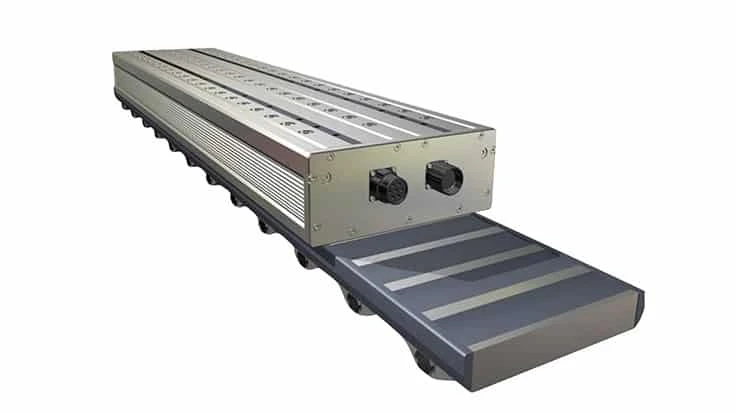

With the recent introduction of its 1FN6 linear motors, Siemens now offers three models of linear motors for seamless integration with all Sinumerik or Simotion control systems using Sinamics drives. Linear scales for position and velocity feedback are available from a variety of third-party suppliers to suit the application. The new linear motor models offered by Siemens are:

1FN3 Peak Load Motors: Short time, high acceleration/deceleration and velocity rates comparable to S3 duty. Can be used for horizontal or compensated vertical axes. Nominal Force (Fn) 8,100N. Maximum Force (Fmax) 20,700N. Maximum velocity 253m/min with liquid cooling.

1FN3 Continuous Load Motors: Long power-on duration for horizontal, inclined or compensated vertical axes. Comparable to S1 duty. Nominal Force (Fn) 10,375N. Maximum Force (Fmax) 17,610N. Maximum velocity 129m/min with liquid cooling.

1FN6 Magnet Free Secondary: Ideal for long traverse lengths at high acceleration and velocity rates. Magnet free secondary and air convection cooled design. Can be used for horizontal, inclined, or compensated vertical axes. Nominal Force (Fn) 2,110N. Maximum Force (Fmax) 8,080N. Maximum velocity 532m/min with air convection cooling.

Note: 1FN3 Peak and Continuous load motors can be run with air convection cooling, however ratings must be reduced by 50%.

One linear motor stationary track (either with magnets or magnet-free) can support multiple primary sections moving either the same slide in a master-slave configuration or moving separate slides independently at different rates and in different directions. This allows the designer to consolidate drive systems on multiple slide machines for cost efficiency and better productivity.

When moving large heavy gantry style slides, multiple primary sections can be used on either side of the moving gantry to provide the force necessary to accelerate and decelerate the slide to optimally productive velocities. In addition, multiple secondary tracks can be installed side by side, if additional force is needed.

On moving slides where cable length or movement is a problem, one or more primary sections can be fixed to a stationary base and the secondary sections attached to the moving member. This lightens the load on the moving slide and allows cycles that include high oscillation rates that might otherwise be impossible with conventional mechanical drive systems. It also allows shorter cable lengths with less flexing.

Advantages of linear motors in machine applications:

- Outstanding dynamic response

- High acceleration/deceleration

- High traverse velocity over long distances at constant speeds

- Backlash free positioning; no longer any need for “Ballscrew Compensation”

- Easy installation with a minimum of components

- Contactless drive with no mechanical wear

- Design flexibility; primary sections can be stationary or moving