Digitalization is marching on in the manufacturing industry, too. However, many machines and plants are not equipped to keep pace with this development. With Industrial Edge, we are offering you a key tool to help you on your way to the digital factory of the future.

The term edge computing simply means shifting computing power to the edge of a network.

With traditional local computing, the necessary devices are installed and set up once. Data transmission is mostly performed through local networks or external storage media. Updating devices always involves intervention in IT infrastructure, which is why it is rarely done.

Cloud computing is the exact opposite. Here, data is transferred to a central data center, processed, and the result re-imported. While the cloud’s data center is very powerful, the potential volume of data is quickly restricted by the bandwidth of the connection, meaning that it is not possible to use all process data that is generated using the cloud.

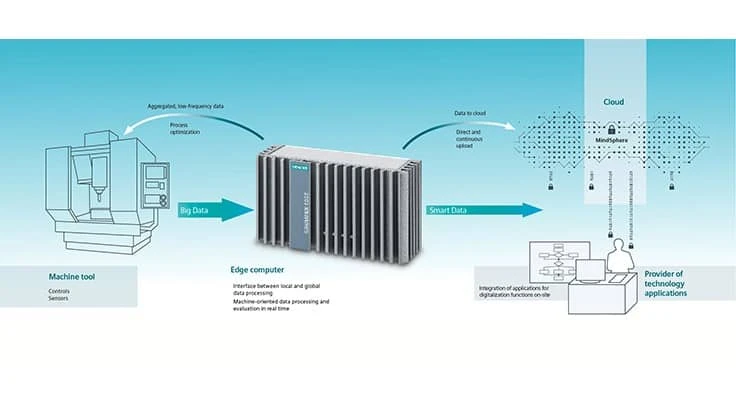

Edge computing technology is an interface between local and global data processing. A powerful industrial computer is located at the machine, facilitating resource-friendly processing of data streams. It also functions as an interface with the cloud, which will now be supplied with processed data – meaning less data traffic. Machine-oriented processing makes it possible to process and effectively utilize even high-frequency data that permits only a short check-back indication time (latency).

Computing at the edge

But what exactly is Industrial Edge? This digitalization platform is much more than just a hardware item. With the help of highly refined analytics, it expands existing automation procedures to include machine-oriented data processing – directly within manufacturing companies. Applications are managed and installed via the cloud.

This means that Industrial Edge has an advantage over local networks in that applications can be updated at any time without having to intervene in the production process. Direct connection to the cloud also allows Industrial Edge to upload processed data directly and continuously.

Machine tools generate up to 2MB of process data per second. Uploading this data to the cloud from several machines is not possible. Therefore, intelligent algorithms must be used to reduce the volume of data. Big data is turned into smart data, and Industrial Edge combines local, efficient data processing in automation with the advantages of the cloud.

Why industrial edge?

The Siemens concept combines hardware and software to bring production and manufacturing data together with globally quality-assured edge computers that are tailored to the relevant digitalization task.

You might think that machine tools equipped with Sinumerik CNC already have a very powerful processing unit that will cover these tasks. The Siemens CNC controller does indeed feature powerful processing units, but the core competence of a numerical control unit (NCU) is path and speed control, which is ensured by the machine builder. The architecture of the CNC machine is tailored precisely to this core competence. Although computing power for additional data analysis algorithms may exist, sufficient capacity cannot be guaranteed.

With this in mind, Industrial Edge facilitates the integration of applications from various sides. Applications from both Siemens and machine tool builders are made available. In addition, Industrial Edge will create a relatively open environment in which. various technology providers and tool and work-holding manufacturers can develop their applications.

Direct implementation into the CNC would not be possible because these have already been customized by the machine builders and do not offer a uniform platform. This customization is necessary because machine tool builders have to guarantee the productivity and quality of the machining process. Industrial Edge is separate from this system and offers a foundation for other technology providers.

The aim is to create a new business segment around Industrial Edge that various providers can utilize. With crossindustry influences and global developers of applications, Industrial Edge should become established as a platform for digital transformation. To this end, Industrial Edge has its own development platform for easy and fault-free programming of applications. Runtime software ensures connectivity with connected automation devices and with the Edge Management system. This connection is an interface to the IIoT cloud. It facilitates further processing of data in higher-level IT systems as well as administration and updating of the applications themselves.

Open to all applications

Industrial Edge is not only used for analyzing and processing CNC machine process data, but it also offers a platform upon which data from another sensor technology installed in the machine will be processed. For example, camera images can be constantly evaluated in order to be able to mechanically monitor component clamping. Results of the data processing by Edge applications will be imported directly back into the machine, therefore optimizing the current process and minimizing wear and improving quality.

Edge computing is going to be a core aspect of machine tool use in the future. Only by using applications with a specific technological background can further increases in productivity be achieved. Industrial Edge creates an environment that facilitates real-time data evaluation – laying the foundation for use of future-oriented technologies.