Optimal Engineering Systems, Inc.

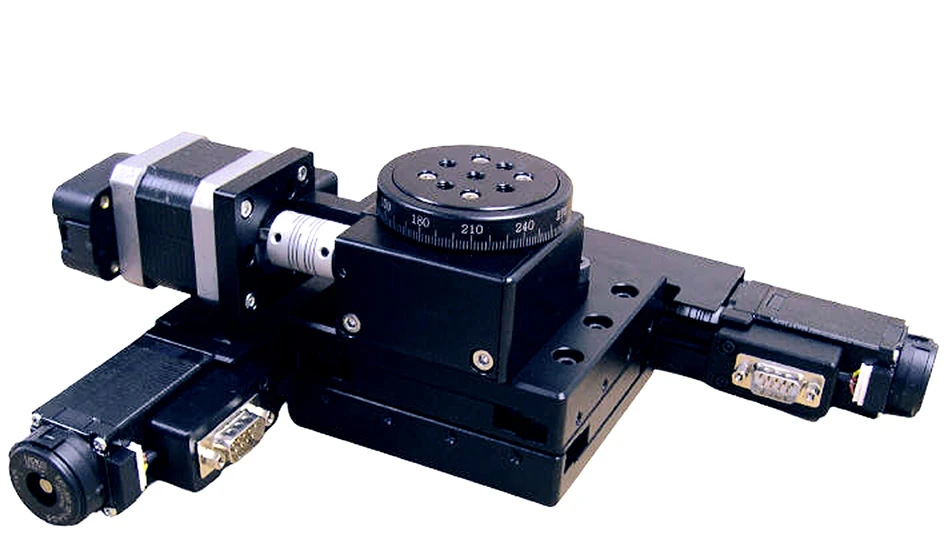

Two new XY-Theta Alignment Stages have been released by Optimal Engineering Systems, Inc. (OES). The XYR-15-60-01 and the XYR-15-60-04 Alignment Stages feature 15 mm (0.58 in.) of travel in both the X and Y axes and 360 degrees of continuous rotation on the rotary axis. The new XY-Theta Alignment Stages are driven by Two Phase Stepper Motors featuring 0.25 micron resolution (20 Micro-steps per Step Motor Driver in use). The XYR-15-60-01 has knobs for manual adjustment and the XYR-15-60-04 (pictured) has 500 Cycles-per-Revolution Quadrature Encoders for position verification. The X and Y axes have 1 mm-per turn precision lead screws, V-groove crossed roller bearings, and limit switches at both ends.

The Theta (rotary) stage is 60 mm (2.362 in.) in diameter with four threaded holes for easy integration of tooling and fixtures, a 90:1 worm gear and precision bearing for smooth travel and home switch. The compact XYR Alignment stage has a total footprint of 238.0 mm by 238.0 mm (9.370 in. by 9.370 in.) and including the Theta stage is just 87 mm (3.425 in.) high.

The typical applications include: Alignment, testing, inspection, scanning, laser drilling, machining, semiconductor handling, sampling, assembly, and optical applications in industrial, medical and research applications. The XYR Alignment Stages can be ordered as complete plug-and-play systems with compatible Motion Controllers with PC interface, joystick, and keypad from OES.