Lubrizol Engineered Polymers is pleased to announce that their ESTANE 3D TPU M95A powder TPU has passed skin sensitization and cytotoxicity tests in accordance with ISO 10993-5 and 10993-10. This enables ESTANE 3D TPU M95A to be a valuable material solution for product designers exploring 3DP for end-use applications that require skin contact. This achievement builds on Lubrizol’s long legacy of developing innovative materials safe for use in skin contact applications – from consumer products to medical devices – and reflects Lubrizol’s ongoing mission to improve lives.

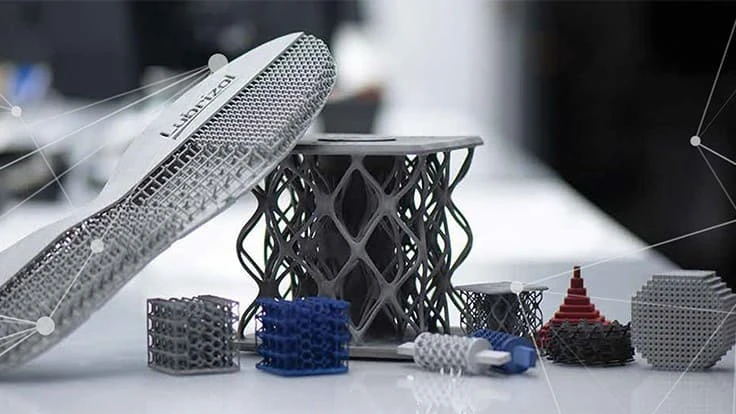

Skin contact suitability is the latest attribute to round out a broader list of benefits that ESTANE 3D TPU M95A brings to applications, including high levels of flexibility, durability, impact and chemical resistance, and energy rebound. Commercially available, ESTANE 3D TPU M95A is certified for use on the HP Jet Fusion 4200 series 3D printing solution – the only TPU certified as such. With an existing installed base, 3DP can be immediately deployed to helping solve critical supply shortages for Personal Protection Equipment needed to battle the COVID-19 pandemic.

David Pascual, Lubrizol’s global commercial 3D Printing lead, announced, “After first developing a new innovative powder TPU for use with the market leading HP 3D printing platform, it is a great step forward for this material to pass this skin sensitivity testing protocol.”

Pascual adds, “This will benefit product designers who are developing applications that require skin contact including personal protection devices so urgently needed right now to protect responders and caregivers fighting the COVID-19 battle. TPU’s versatility, durability and barrier properties bring value in these vital applications”.

Skin contact clearance also benefits applications in footwear, prosthetic and orthotic devices, and wearables for electronic devices where the benefits of energy rebound and impact absorption are particularly important.