HEIDENHAIN

HEIDENHAIN CORPORATION will be exhibiting at Automate, Booth #3641, May 22-25 in Detroit, Michigan. The HEIDENHAIN booth will highlight cutting-edge solutions for robotics and motor manufacturers, including:

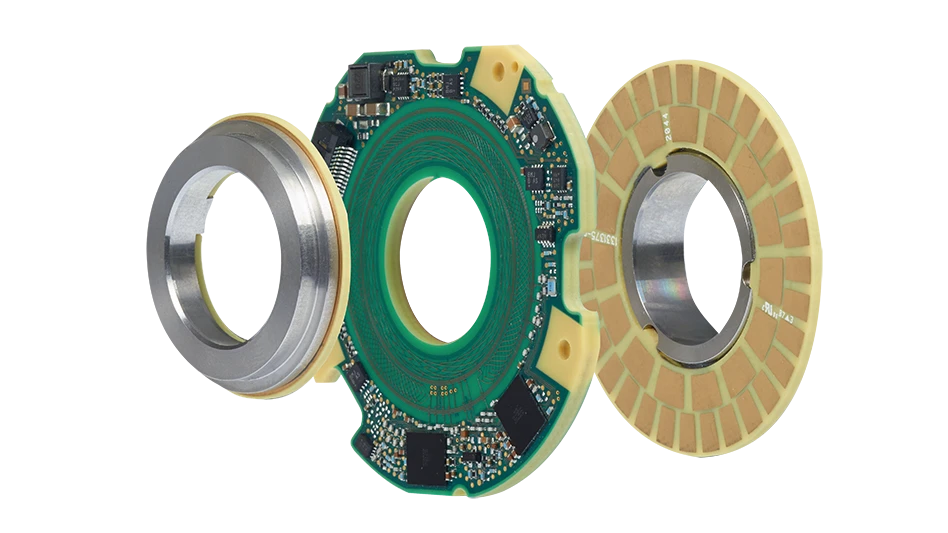

- The KCI 120 Dplus dual encoder, which provides motor feedback and position measurement in a single device. Installed downstream from the gear system, it enables the compensation of design-related inaccuracies in dynamic robots, such as joint elasticity, zero-position error, reversal error, and machining effects. Visit the booth to see the technology in action in ABB’s GoFa collaborative robot arm.

- EnDat 3 is the latest version of HEIDENHAIN’s absolute position encoder interface. In addition to increased speed, memory and storage, EnDat leverages the industry standard for functional safety (black channel) and supports pre-certified Functional Safety encoders (like the ECN 1100 and EQN 1100 series) with capability up to SIL 3 PLe. Finally, EnDat reduces cabling and overall system costs, because EnDat-enabled encoders can integrate with single hybrid motor cables from HEIDENHAIN in the HMC 2. This allows automation OEMs to transition from dual-cable motor outputs to single-cable outputs for more cost-efficient manufacturing.

- A wide variety of solutions for general automation needs from the entire HEIDENHAIN family of brands, including the small-format, cost-efficient LIKgo from Numerik Jena, robust inductive encoders from AMO, heavy-duty Industrial encoders from LEINE LINDE, and slip rings from LTN and more.