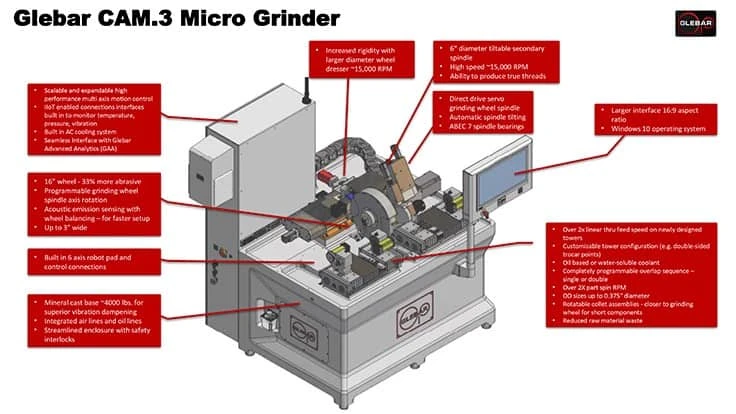

Glebar will be exhibiting at MD&M West in Anaheim, California, booth #2059, unveiling its CAM.3 micro grinder along with recently acquired Tridex Technologies and its CS-1 Electrochemical Cutoff Machine. Highlights include:

• Scalable and expandable high performance multi axis motion control

• IIoT enabled connections interfaces built in to monitor temperature, pressure, vibration

• Built in AC cooling system

• Seamless interface with Glebar Advanced Analytics (GAA)

• 16” wheel - 33% more abrasive

• Programmable grinding wheel spindle axis rotation

• Acoustic emission sensing with wheel balancing – for faster setup

• Up to 3” wide

• Built in 6 axis robot pad and control connections

• Mineral cast base 4,000 lb for superior vibration dampening

• Integrated air lines and oil lines

• Streamlined enclosure with safety interlocks

• Increased rigidity with larger diameter wheel dresser 15,000rpm

• 6" diameter tiltable secondary spindle

• High speed 15,000rpm

• Ability to produce true threads

• Direct drive servo grinding wheel spindle

• Automatic spindle tilting

• ABEC 7 spindle bearings

• Larger interface 16:9 aspect ratio

• Windows 10 operating system

• Over 2x linear thru feed speed on newly designed towers

• Customizable tower configuration (e.g. double-sided trocar points)

• Oil based or water-soluble coolant

• Completely programmable overlap sequence – single or double

• Over 2X part spin RPM

• OD sizes up to 0.375" diameter

• Rotatable collet assemblies - closer to grinding wheel for short components

• Reduced raw material waste