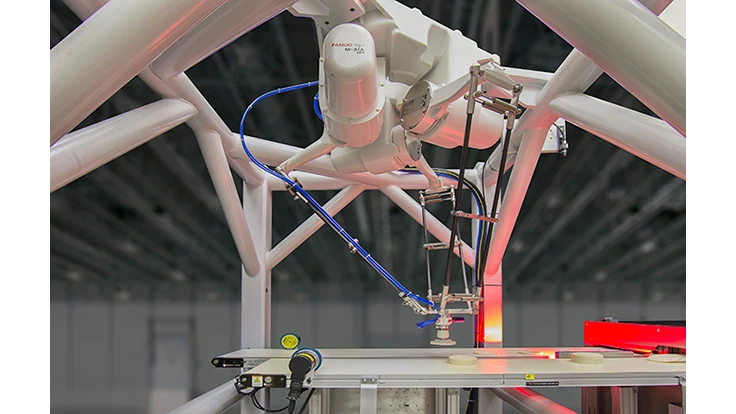

Rochester Hills, Michigan – Fanuc America Corp.’s M-3iA robot is a larger version of the company’s M-1iA and M-2iA Genkotsu robots. Available in a 3-, 4-, or 6-axis model, the M-3iA offers the same parallel-link structure, and accommodates payloads up to 12kg. In addition, it has the largest work envelope of any robot in its class (1,350mm x 500mm).

The M-3iA/6A 6-axis model has a three-axis wrist for complex assembly tasks, enabling the robot to pick up and insert parts at simple or compound angles, and twist parts into place, similar to the flexibility offered by a manual operator.

The 4-axis M-3iA/6S has a single-axis wrist for simple assembly and high-speed picking operations, offering speeds up to 4,000 degrees per second.

In addition, a hollow wrist allows hoses and cables to be routed internally, which minimizes wear and tear on the tooling cables.

A 3-axis M-3iA/12H has up to 12kg payload and offers higher throughput when the applications do not require orientation control of the product.

The M-3iA, like all Fanuc robots, operates with the company’s latest R-30iB controller with integrated intelligent functions such as iRVision, force sensing, robot link, and collision guard.

The M-3iA Genkotsu robot offers a wide range of benefits, including:

- Patent-pending 3-axis, parallel-link wrist maximizes flexibility

- 6-axis design (3-axis wrist) enables part feeding from the sides of a work zone, increasing the useable workspace

- 4-axis design (single-axis wrist) moves parts at extremely high speeds; a hollow wrist allows tooling cables to be routed internally, minimizing wear and tear

- 3-axis design operates at high speeds and offers a 12kg payload

- IP67 rating for the entire robot means the robot is waterproof and can withstand harsh environments, including dust and oil mist

- Collision guard detects robot collisions with external objects, minimizing damage to the part and robot

- Robot link controls and coordinates up to 10 robots through a network exchange of robot positional data

- Fanuc force sensor is available for intricate assembly applications

Fanuc iRVision

An integrated, plug-and-go vision system that runs on the standard CPU of every Fanuc R-30iB controller without any additional hardware, Fanuc iRVision is a single source solution developed and supported by Fanuc, offering easy setup and operation for factory environments requiring 2D and 3D guidance, error proofing, visual tracking, and quality control.

R-30iB mate controller

The Fanuc R-30iB mate controller uses high-performance hardware and the latest advances in network communications, integrated iRVision, and motion control functions. The R-30iB mate controller features Fanuc’s exclusive and easy-to-use iPendant with 4D graphics. The iPendant displays process information and the actual process path directly on the iPendant screen, enabling easier setup and troubleshooting.

Based on the latest Fanuc series 30iB CNC controller, the R-30iB mate robot controller is compact, providing customers a significant space savings. The R-30iB mate controller, available with a compact rack-style open-air controller cabinet or an industrial grade standard mate cabinet, is very energy efficient and requires less power consumption due to its availability in both single-phase and three-phase versions.

Source: Fanuc America Corp.