DuPont’s Delrin acetal resin features the lowest coefficient of friction (COF) in the company’s portfolio of materials for medical devices. The DuPont Delrin SC698 resin with integrated lubrication can help improve patient comfort and ease of use by ensuring smooth actuation of high-load drug delivery devices such as inhalers, injectors, and pumps. Its strength, stiffness, and dimensional stability can help increase the injection precision of wearables and inserter devices.

Lowest friction for easier operation

Patient compliance and positive outcomes depend on using a drug delivery device as prescribed, and on achieving dose-to-dose accuracy and consistency. DuPont Delrin SC698 resin can help meet both requirements. Its combination of very low COF and excellent mechanical properties (high strength, dimensional stability) help facilitate device actuation and ensure consistent, precise drug delivery each time.

Enhanced wear resistance

Delrin SC698 resin is a highly crystalline homopolymer offering strength, stiffness and fatigue resistance. Together with ultra-low friction, these properties deliver excellent wear performance over time and repeated use to promote an extended useful life. In addition, the material’s high impact resistance helps protect against damage from drops.

Support for device miniaturization

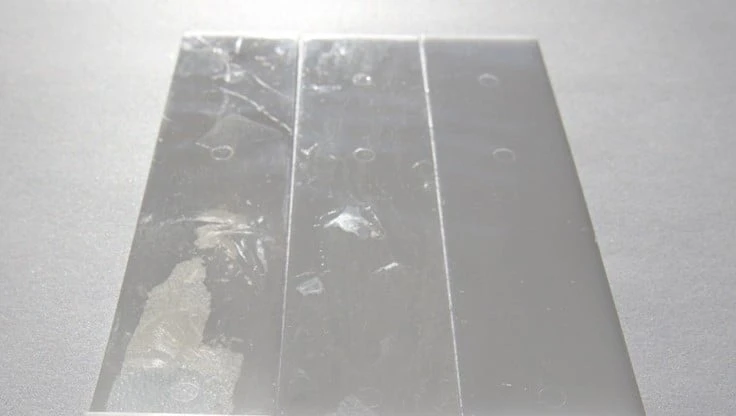

The strength, rigidity, and dimensional stability of Delrin SC698 resin allows designers to create thin-wall, complex, and miniaturized designs without sacrificing performance. Other benefits for healthcare manufacturers include integrated lubrication, which avoids the need for secondary operations to add lubricity, and system cost reduction opportunities through high-volume injection molding.

Special control

The SC designation in Delrin SC698 resin stands for special control. DuPont SC resin grades undergo an extensive amount of testing and offer a great degree of manufacturing control and broad regulatory compliance.