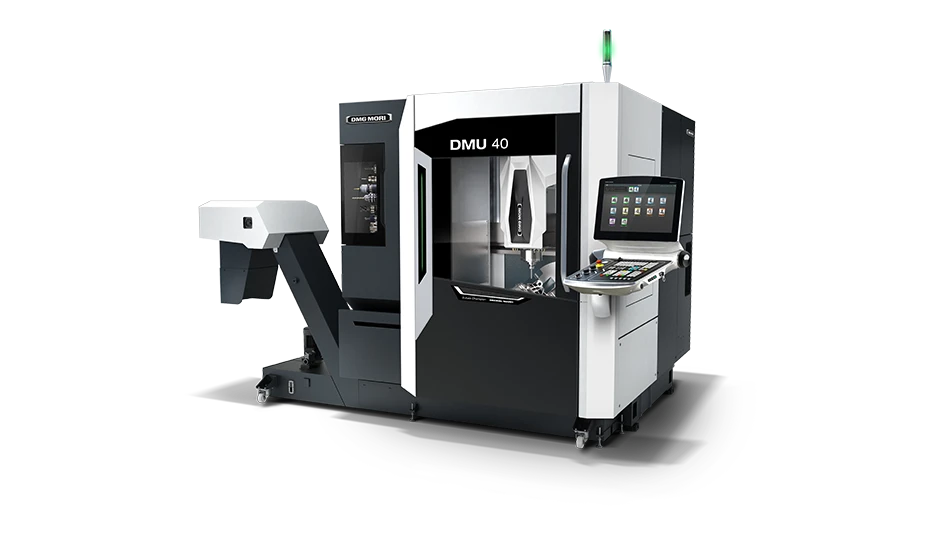

CREDIT: DMG MORI

More than 10,000 sold machines of the DMU 50 3rd Generation prove that compact and attractively priced universal machines for 5-axis simultaneous machining have a high value in numerous industries. With the new DMU 40, DMG MORI is explicitly responding to this demand in the entry-level sector for versatile manufacturing solutions for complete machining. The machine is based on the concept of the DMU 50 3rd Generation and features best-in-class components from the spindles to the direct drives in the X and Y axes, as well as preparation for automated production with a PH 150 or Robo2Go. Three basic machines – DMU 40, DMU 40 PLUS and DMU 40 PRO – meet individual requirements up to the highest precision in the µm range. In short, the DMU 40 offers many of the advantages of the DMU 50 3rd Generation at the lowest entry price in the market segment for 5-axis simultaneous machining.

A space-saving design with a machine width of less than 2m and a generous work area with traverse paths of 550mm x 450mm x 420mm make the DMU 40 an ideal companion in production areas with limited space. In its development, DMG MORI placed emphasis on a stable design. The one-piece machine bed made of gray cast iron, the geometry-optimized Y and Z slides, and the inline spindle with hydraulic clamping ensure high rigidity and thus the basic building block for optimum machining results. In addition, the tool magazine has an optimized connection that has less influence on the machine geometry. Direct-drive ball screws in the X and Y axes improve surface quality. For the most versatile 5-axis simultaneous machining possible, DMG MORI has also integrated the proven swivel rotary table of the DMU 50 3rd Generation into the DMU 40. For even more flexibility, the swivel range of the B axis extends from -35° to 110°.

Optimum ergonomics for comfortable operation

The ergonomic design of the DMU 40 offers optimum accessibility to the work area. The table loading height is 800 mm while maintaining a short distance from the operator to the table center. The large window and improved lighting provide perfect visibility into the work area and loading of the machine is also possible by crane to the center of the table. Optionally, the tool magazine can be loaded from the front.

Three basic machines: The perfect solution for every requirement

DMG MORI has designed the DMU 40 in three different basic machines to meet different production requirements. The standard version already includes an inline spindle with 12,000rpm, the tool magazine with 24 places, and the integrated 5-axis swivel rotary table. Thus, the entry-level model already enables the requirement for 5-axis simultaneous machining. The DMU 40 PLUS features a 15,000rpm inlineMASTER spindle and a tool magazine with 30 places. Direct absolute path measuring systems, the extensive passive cooling of all main components by means of heat exchangers further extend the machining spectrum. The DMU 40 PRO achieves the highest positioning accuracy of 5µm according to ISO 230-2, the highest positioning accuracy. The main components are actively cooled here. In addition, there is a speedMASTER spindle with 20,000rpm.

Automation solutions from a single source

As a pioneer in the automation of machine tools, DMG MORI has also taken this topic into account for the DMU 40. The universal model can be optionally expanded to include the PH 150 pallet handling system or Robo2Go Milling. This allows customers flexible and autonomous production even in unmanned night and weekend shifts.