The CHIRON Group

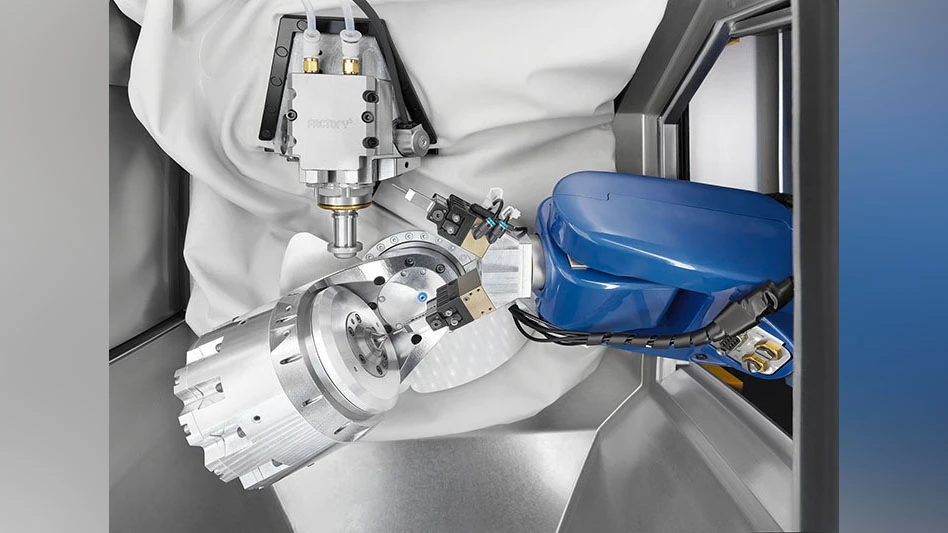

In a very short amount of time, the smallest and most energy-efficient machine in the product portfolio of the CHIRON Group has become a bestseller. The USPs of the Micro5 are sustainable and ultraprecise. This machining center features an energy requirement of just 0.5kW/h, a footprint of under 1m2 and micron-level precision. Together with the automation Feed5, the Micro5 features high autonomy. With a workpiece blank of 50mm x 50mm x 3mm (capacity of more than 1,200 blanks) and an assumed cycle time of ten minutes, that equates to eight days of automated production.

Machine highlights

- High-precision 5-axis machining

- Ultra-compact machine

- Machining cube max. side length 50mm

- High-static rigidity and repeat accuracy

- Outstanding thermal stability

- High-speed cutting

- Low energy consumption <500W

- Precious metal recovery

- Magazine with 60 tools in the working area

- Palletizing with up to 6 pallets in the working area

- Easy access for service and maintenance

- Excellent view of the production process

- Easily automated with Feed5

The Micro5 and Feed5 will demonstrate dynamic and productive high-speed milling at EMO Hannover 2023 and will be a real eye-catcher for everyone working in precision technology.