Absolute Machine Tools with Productive Robotics will exhibit the lineup of collaborative robots (cobots) at IMTS 2022 (booth #338519). There will be an area designated for free play, allowing attendees to get a hands-on experience. The four different OB7 cobots in the series are engineered to handle a variety of payloads and sizes while accomplishing simple to complex tasks. Due to the skills gap and employment shortage, cobots play a vital role in manufacturing operations now more than ever.

Fully compliant with ISO 102018-1 industrial robot safety requirements, OB7 cobots can perform operations such as machine tending, deburring, applying adhesives, painting, welding, and assembly without the need for fencing to isolate them from human coworkers.

To facilitate application, OB7 cobots are built with a true 7th axis inside the unit’s arm, rather than 6 axes. Most cobots on the market today are built with only 6 axes or include rails or other accessories to claim a seventh axis. The 7th axis on an OB7 is built-in and allows the cobot to be positioned at the side of the machine door, so it doesn’t block operator access to the work envelope for changing things like tooling or inserts.

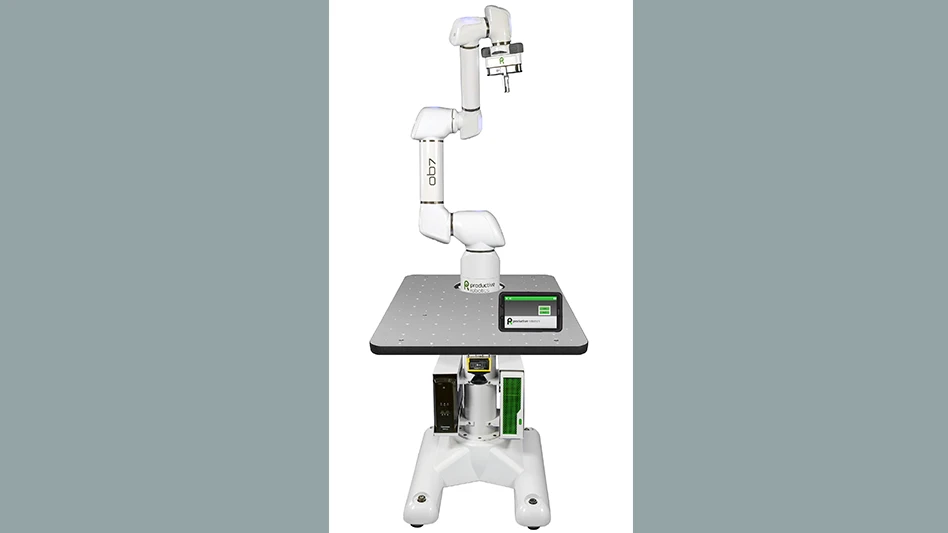

Because OB7 cobots are programmed on a teach platform, they don’t require coding or programming, and any shop personnel can teach the cobot new tasks by manually moving the arm of the cobot and dragging and dropping tiles on the control tablet interface. Pre-programmed tiles are available in the OB7 tablet, and custom job functions for complex or repetitive tasks can be created, labeled, and saved for future recall. The OB7’s computer controls all axis joints and components, and network ports are locked to prevent unauthorized access. A rolling stand with integrated casters enhances portability and usability, and an assembly table on the stand provides a work surface for stacking blanks and collecting finished parts, allowing for constant and continuous production of product.

OB7 CNC packages come equipped with a standard end-effector or end-of-arm single parallel gripper that can be applied in hundreds of production applications. An adapter plate can be added with a second parallel gripper providing dual gripping for fast finished parts and material changes. OB7 cobots are compatible with most end-effectors and end of arm tooling attachments because users can adjust gripping force, speed, and opening position manually or automatically through the tablet. Collaborative capability can be adjusted to fit specific production situations. When running at safe speeds, no guarding is required. To operate at higher speeds and prevent collisions, an optional laser safety scanner is available with a 270° detection range, 5m protection zone, and 20m warning zone.

Ongoing software updates enhance connectivity, expedite efficient integration with other equipment, and facilitate real-time status monitoring with email and text alerts.