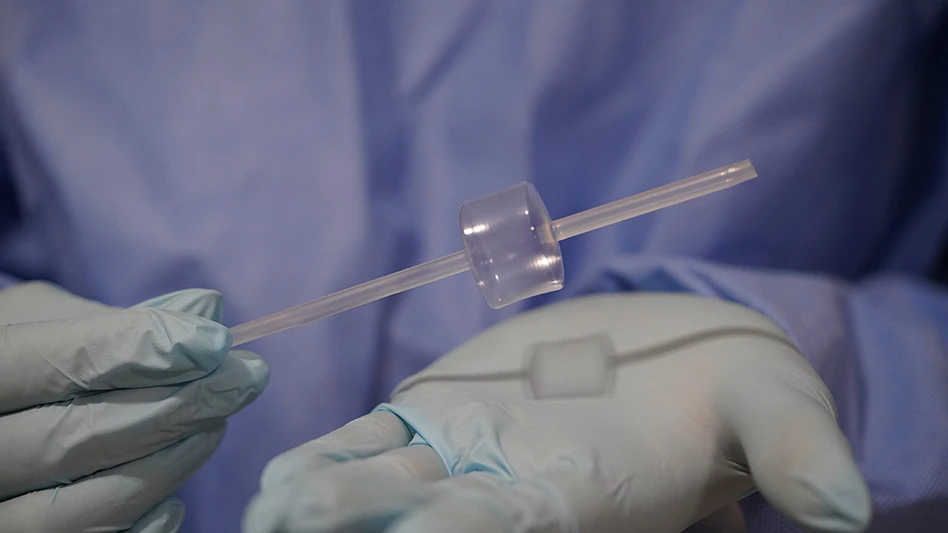

CREDIT: POBA MEDICAL

US Extruders will collaborate with Colin Sutherland of Wexford Ireland to provide complete engineered systems for balloon tubing and balloon forming technologies. Colin Sutherland is recognized as a worldwide technology leader in specialty balloons for interventional, surgical & specialized applications. US Extruders develops medical extruders designed for tight tolerance medical tubing applications with high process capabilities.

The agreement includes the integration of Colin Sutherland’s automated balloon forming technology and expertise to develop and manufacture balloon designs from Nylon, PET, Pebax, TPU and custom blends. US Extruders will deliver a 25mm Med-Ex extruder that will be installed in Colin’s new development center located in Wexford, Ireland. In addition to a complete extrusion line and balloon forming equipment, in-house catheter manufacturing capabilities include molding, UV bonding, thermal bonding, laser welding, micro TIG welding, wire EDM, 3D printing capabilities and more. The new development center combines complete design, prototyping and testing capabilities on beautiful grounds located in Wexford, Ireland that includes three remote guest pods surrounded by beautiful nature walks and healing ponds.

“Poba Medical is excited to partner with Colin and anxious to evaluate the next generation balloon forming technology in a high-volume manufacturing environment. Colin’s passion as a toolmaker and recognized thought leader in balloon blow molding will be clearly exemplified in his state-of-the-art equipment offering to support next generation interventional balloons well into the 21st century,” states Dan Kasprzyk CEO of Poba Medical. Our ability to rapidly test new equipment platforms under rigorous R&D and manufacturing conditions makes Poba Medical an ideal partner. We are approaching 1000 unique off-the-shelf balloons that are now available on Chamfr.com. Additionally, we just launched a Quick Turn offering with over 125 unique SKU’s available to ship in 3 weeks or less. We look forward to expanding our online offering to further service engineers iterating in product development.

According to Colin Sutherland, “high quality balloon manufacturing starts with highly concentric balloon tubing that meets very stringent elongation properties. By combining the engineering and development of the extrusion system with the balloon forming process, we will be able to offer a complete and highly integrated solution to medical device companies.”

In partnership with the medical material solutions provider, Compounding Solutions, the Med-Ex extruder will be used to develop and test innovative materials for balloons and catheter shaft applications.

As part of the agreement, Colin Sutherland will represent US Extruders in Europe for the sale of medical extruders and extrusion systems.

Latest from Today's Medical Developments

- Teradyne Robotics debuted AI accelerator-powered solutions at NVIDIA GTC 2025

- Measurlabs opens a facility in California

- Sumitomo’s AC9115T & AC9125T – Turning grades for titanium

- #41 Lunch + Learn Podcast - SMW Autoblok

- Machine learning framework enhances precision, efficiency in metal 3D printing

- SkillMill – 60-year-old milling machine with digital twin

- Lumetrics’ OptiGauge II EMS

- EMI completes installation of 128-axis CNC turning & milling machine