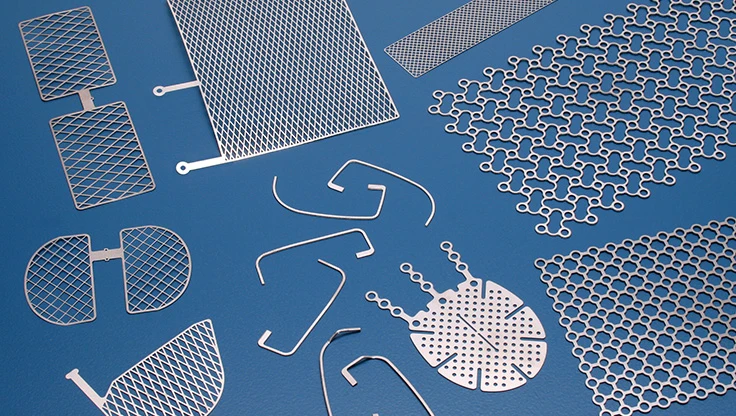

Plymouth, Massachusetts – Tech-Etch specializes in the photo chemical etching of titanium. Because of its low weight, strength, and corrosion-resistance, titanium is used in everything from jet engines to eyeglass frames. Because titanium is inert and completely biocompatible, it is also used in many medical implantation applications such as maxillofacial and craniofacial reconstruction plates, as well as anode and cathode battery current collectors and telemetry antennas found in implanted medical devices.

Tech-Etch supplies component parts made from titanium and other specialty materials such as nitinol, niobium, Elgiloy, tungsten, and polyimide to the medical device marketplace. Parts range in thickness from 0.0005" and up. Providing quick turnaround and low tooling costs, photo etching produces burr-free parts with intricate and complex shapes. Designs can be proved in preproduction quantities without having to commit to expensive tooling.

Source: Tech-Etch

Latest from Today's Medical Developments

- EMO: Made for game changers

- Thomson’s encoder options for stepper motor linear actuator online selection tool

- BD boosts US manufacturing of critical medical devices

- Aerotech’s HexGen HEX150-125HL miniature hexapod

- World-leading medical device supplier via a new merger

- Edge Technologies' FMB Turbo 3-38 RS bar feeder

- Mazak’s new Customer Solutions Center

- maxon's High Efficiency Joint (HEJ) Drive