Michigan Metrology

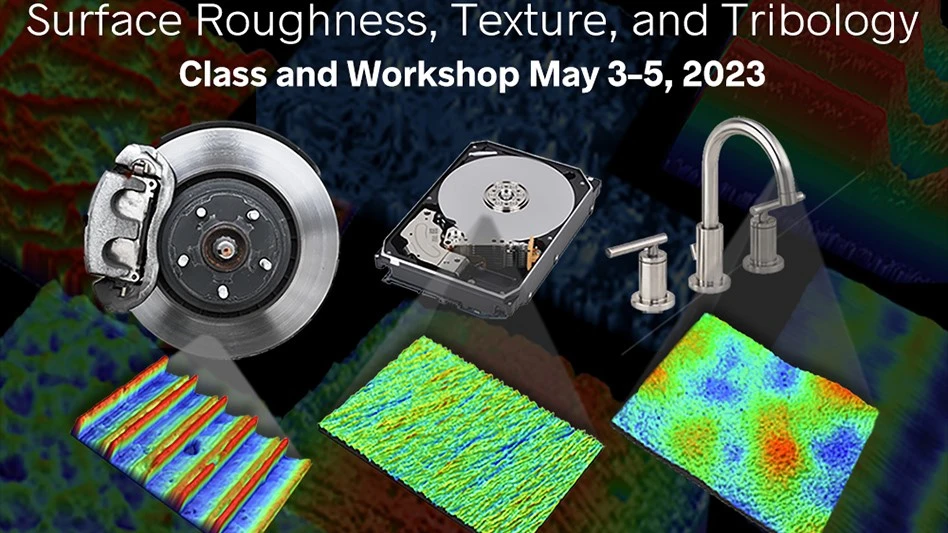

Registration is open for the Roughness, Texture, and Tribology class and workshop, which will be held in Livonia, Michigan, May 3–5. 2023. This class offers a unique opportunity to learn the fundamentals of surface roughness, friction, and wear, as well as the application of surface texture analysis in industry and research.

“This class is intended to help students to use surface roughness analysis in their workplaces,” said Don Cohen, PhD, who presents the course. “Live lectures and hands-on training with measurement equipment give our students a chance to ask questions and really learn what matters for their particular jobs.”

The class offers a deep dive into topics including:

- Measuring roughness and waviness

- Instruments for surface measurement

- Filtering texture data for the application

- Data analysis techniques and tools

- Surface texture parameters

- Specifying surface texture

- Applying surface texture analysis to wear, sealing, and other functionality

- Surface energy, adhesion and texture, paint appearance

- Mechanics of dry friction and rolling friction

- Fundamentals of lubrication

- Surface metrology strategy.

The 2 1/2-day class will be presented live, in accordance with CDC guidelines to prevent the spread of the COVID-19 virus.

“We have been refining and expanding this class for nearly 20 years,” says Dr. Cohen. “It’s the most thorough and affordable opportunity we know to learn and apply the fundamentals of surface texture analysis.”

Class details and registration are available at michmet.com/classes. Registration requests can also be made by calling 866.953.5030 or emailing info@michmet.com.

Latest from Today's Medical Developments

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business

- ZOLLER events will showcase the company’s cutting-edge innovations

- THINBIT’s MINI GROOVE ‘N TURN Acme threading inserts

- CMMC Roll Out: When Do I Need to Comply? webinar

- Metabolic research uses Siemens gas analyzers to deliver results with 99.9999% resolutions

- Mazak’s SYNCREX 38/9 Swiss-type production turning machine

- Current economic and geopolitical realities demand decisive action