Pittsfield, Massachusetts – Jana Care, a medical technology company based in Boston, Massachusetts, has selected China Array Plastics, an engineering and injection molding company specializing in high-performance polymers with offices in Pittsfield, Massachusetts and Wuhan, China, to prototype and manufacture its new Aina Mobile Blood Monitoring System. Jana Care, which is tackling the challenges of managing diabetes and other chronic diseases with affordable diagnostics and mobile technology, sought China Array Plastics’ expertise to optimize the manufacturability of the Aina diagnostic sensor while accelerating time to market and keeping costs down.

Jana Care was referred to China Array by another company in the Boston medical device community through its connections to the Massachusetts Institute of Technology (MIT).

“Having taken the Aina concept as far as CAD and 3D printing could carry it, we needed to move on to injection molded prototypes followed by rapid, scalable manufacturing,” says Michal Depa, Jana Care’s chief technology officer. “China Array was well suited to the task. Its molding facility in Wuhan, China was a great option to keep the cost of the device affordable, which is key to our goal of maximizing usage in all geographies. We're both also headquartered in Massachusetts, which streamlined engineering.”

Carl Olson, vice president of marketing for China Array, explains, “We identified a tough, affordable and easily installed reflective substrate that met Jana Care's light specifications and developed a housing that held the reflective surface in an immutable position for accurate, repeatable testing. The housing also fully protects the reflectivity chamber from environmental impacts, which is particularly important for a device used by the general public.”

For the sensor housing components, China Array identified a high-heat, medical grade polycarbonate/acrylonitrile-butadiene-styrene (PC/ABS) blend with a proprietary texture applied, giving the part the attractive appearance, impact strength, low cost and biocompatibility that Jana Care required.

After an overall design review to improve manufacturability (and affordability), China Array built hybrid prototype/small production tooling, which allowed Jana Care to obtain several thousand units for clinical and field trials in Asia and the United States. Based on the trials, China Array modified these molds to achieve the desired functionality for production tooling.

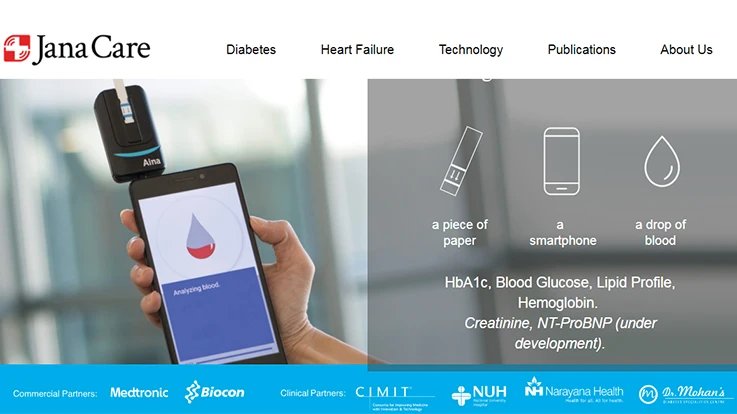

The Aina diagnostic sensor plugs into any smartphone and analyzes HbA1c, blood glucose, hemoglobin and lipids from a capillary blood sample placed on a reactive test strip. It can be used by patients for self-monitoring and by healthcare providers for mass screening and point-of-care testing. The Aina sensor is the core of a mobile platform that uses biochemistry, optical sensing, software algorithms and behavioral science to combat diabetes and other chronic diseases at greatly reduced costs.

The Aina device is CE-marked and widely used in Asia. Jana Care is currently working on scaling it to other geographies across the world, including preparing for US market entry.

Latest from Today's Medical Developments

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series