Propel

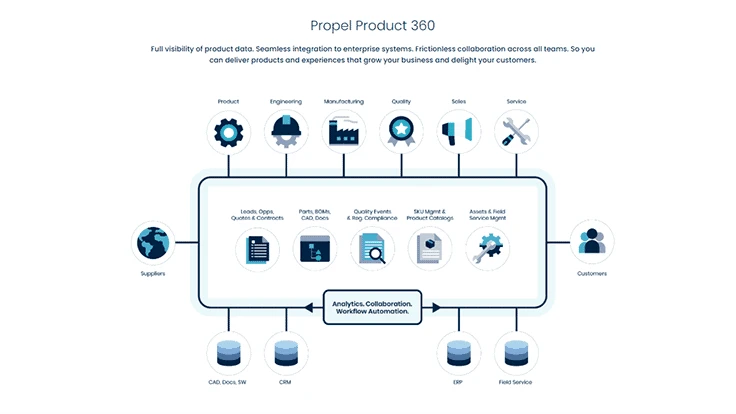

Propel, developer of the only unified quality management (QMS) and product lifecycle management (PLM) solution built on Salesforce, announced the Propel Supplier Community, a new solution to improve supply chain collaboration. It will allow manufacturers to more effectively manage dynamic supply networks within a modern, secure environment optimized for rapid onboarding, continuous performance monitoring, and immersive collaboration.

Manufacturers are adjusting to massive supply chain disruptions across the entire value chain and at every stage of the product life cycle: design, engineering, offshore production and beyond. On premise solutions require workarounds – such as third-party file sharing, VPNs, and external firewall access – which increase risk and overhead. This hinders collaboration, reducing the number of suppliers that manufacturers can productively engage – an outcome they cannot afford in the current environment.

“As manufacturers are constantly challenged to balance risk mitigation, design innovation and cost management, Propel’s Supplier Community enables our customers to extend the value of Product 360 to their strategic and operational suppliers,” said Ray Hein, co-founder and CEO, Propel. “By removing the friction that external users typically confront, this new solution will help manufacturers to easily onboard and collaborate with suppliers anywhere in the world.”

The Propel Supplier Community will be available in calendar Q1 2022 and enables:

- A secure environment for collaboration between original equipment manufacturers (OEMs) and authenticated suppliers to safeguard intellectual property

- An intuitive and configurable role-based user experience to facilitate broad supplier adoption

- Embedded communication associated with the product definition to capture knowledge in context and improve decision-making

- Supplier-initiated change requests to reduce design and change cycle times

- Flexible pricing for OEMs featuring user-based licensing for strategic suppliers and usage-based licensing for operational suppliers to reduce cost of ownership

- Access for contract manufacturers (CMs) and support for a range of business models: Build-to-stock (BTS), engineer-to-order (ETO), and configure-to-order (CTO)

- Closed loop quality management through continuous feedback to improve product quality, reduce warranty expense, and speed issue resolution cycle time

“Just like the focus on the customer experience is driving improved engagement between businesses and consumers, the field of supplier collaboration holds strategic importance for many companies. Every day brings news of new supply chain disruptions,” says Peter Bilello, CEO & president, CIMdata, Inc. “More than ever, product companies need efficient and effective ways to identify, qualify, onboard, and collaborate with suppliers to ensure product quality and business continuity. Propel Supplier Community has the potential to redefine OEM-supplier collaboration with its innovative approach to improving insight and reducing friction within supply networks,” he adds.

Latest from Today's Medical Developments

- Best of 2024: #4 Article – Sticking to the basics

- Best of 2024: #4 News – Point of care manufacturing

- Best of 2024: #5 Article – Accelerating medical device development with freeform injection molding

- Best of 2024: #5 News – Complexity, the enduring enemy of medical cybersecurity

- Best of 2024: #6 Article – Closing the global product information gap

- Best of 2024: #6 News – NUBURU enters medical device market with order Blueacre Technology

- Season's greetings

- Best of 2024: #7 Article – Synchronized machining processes for medtech