Methods Machine Tools

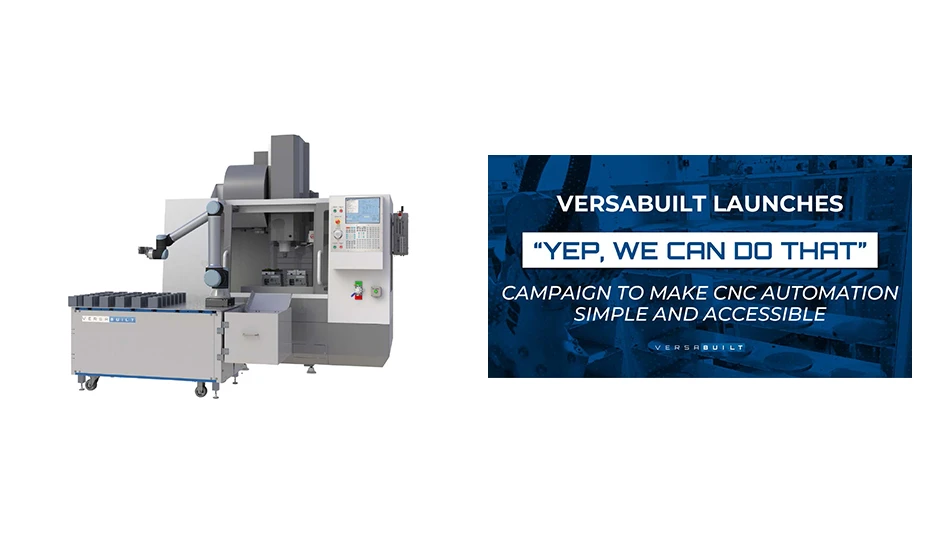

Methods Machine Tools, the foremost supplier of

high-quality, high-precision CNC machine tools, automation, and engineering

services, announces a new commercial agreement with Yasda Precision Tools K.K.

that continues Methods’ role as the single importer, distributor, and service

provider of Yasda’s portfolio of precision machining centers in the United

States.

The formal relationship between

the two companies began in 2014, when Methods began importing Yasda’s lines of

3- and 5-axis lines, including the YBM vertical and horizontal series, YMC

series, and the PX30i and H40i Precision Centers.

“For nearly a decade, we have

held the distinct privilege of offering Yasda’s world-class machines in the

U.S., directly and through our dealer network,” says Dale Hedberg, COO at

Methods. “The continuation of our partnership demonstrates the strength of our

collaboration and focus on delivering Yasda’s unrivaled class of machines,

backed by the highest-quality service and parts fulfillment.”

“As the most advanced and established

machine importer in the U.S., Methods is the best partner to convey, supply,

and support our machining technologies for manufacturers throughout the

country,” says Yasushi Kimura, president of Yasda Precision America Corp.

“Our machine designs and unique

manufacturing processes provide the highest level of accuracy and stability to

satisfy demand for the tightest precision across all industries. Additionally,

with growing needs for automation, Methods’ engineering capabilities expand the

possibilities customers can achieve when working with Yasda and Methods,”

Kimura adds.

Yasda

precision centers, most

commonly found in aerospace, micro-milling, and die/mold facilities, are known

for having the highest CNC machining accuracy in the industry. Capable of

regularly achieving accuracies of 0.001mm, and submicron accuracy in unique

applications, Methods showcases Yasda machining centers at its one-of-a-kind Precision Center located

in Acton, Massachusetts.

“Yasda’s attention to geometric

assembly perfection and thermal stability, combined with exceptional rigidity

and spindle capability, make Yasda the premier machine tool builder in the

world,” says Kevin Lichtenberg, Methods’ product manager for Yasda.

“Whether a shop requires the

tightest tolerances for aerospace, medical, or semiconductor manufacturing

parts or for complex mold shapes, my guidance to manufacturers looking to

separate from their competition is that the precision, market-leading features,

and reliability of Yasda will increase their workpiece quality, reduce

secondary processes and – most importantly – ultimately reduce productions

costs.”

Customer example

PlasticInjection Mold Manufacturer Succeeds with Five-Axis Machining, Automation

Pennsylvania-based X-Cell Tool and Mold leveraged the Yasda YMC650 and

automation to fulfill contracts for ventilator components during the COVID-19

pandemic.

Latest from Today's Medical Developments

- Soft joint model for robots

- TANAKA PRECIOUS METAL TECHNOLOGIES’ Visi Fine

- Auxilium Biotechnologies prints medical devices on the International Space Station

- KYOCERA SGS Precision Tools’ APEX Application Expert

- North American robotics market holds steady in 2024 amid sectoral variability

- Evident’s DSX2000 digital microscope

- Ferrocene becomes first Rust toolchain to achieve IEC 62304 qualification

- Germany expects a major decline in production in 2025