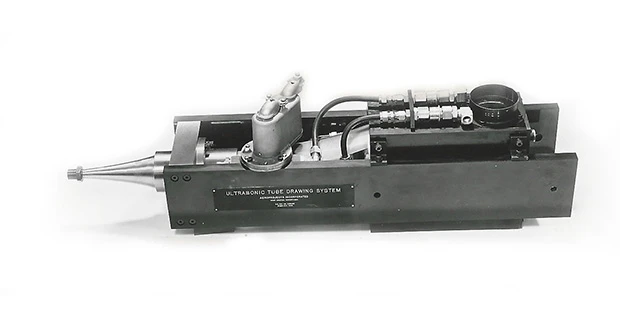

West Chester, Pennsylvania – Sonobond Ultrasonics officials announced that its Tube Drawing System and components are specially designed to accommodate manufacturers of fine metal tubing used in syringe needles, as well as for medical devices and tubing products used in many other industries to transport critical fluids.

“In conventional tube drawing systems, lubricants are used to reduce friction between tooling and metal tubing,” explains Sonobond President Janet Devine. “With our ultrasonic system, high-frequency vibrations create a continuous cycle of increasing and decreasing pressure between tooling and work piece, resulting in less friction and a reduction of force needed for the draw and consequently significant improvement in the internal surface finish of the tube, which is absolutely essential for critical fluid transmission. Optimum results are achieved when the ultrasonic activation is used in conjunction with ‘best practices’ such as lubricants.”

Applying ultrasonic energy to tube drawing operations

In a standard rod draw operation, a controller first positions the tube to be drawn over a long, back support rod, terminated in a plug, so that the tube to be drawn can be loaded onto the machine. Draw carriage jaws then grasp the tube and pull it through a die, which is on the outside of the tube and aligned with the plug, which is inside the tube, thinning the tube walls, and achieving the desired wall thickness and internal diameter. Often multiple draws are required with progressively smaller dies and plugs to reach the desired tube size.

In an ultrasonic system, a power supply converts line power to high voltage, high frequency electrical power needed to drive the transducer, which is attached to a coupler at the back end of the back support rod and mounted on a carriage on the draw bench. The transducer converts electrical energy to vibratory energy. Waveguides or components – typically a tapered coupler and the back support rod, which holds the die and/or plug – carry the vibratory energy from the transducer to the plug. The waveguides are designed to resonate at the frequency of operation of the power supply and transducer, usually in the range from 15 to 28 kilohertz depending on the size of the rod and the tube being drawn.

“The ultrasonic energy reduces frictional forces between the forming tools, and also increases the plasticity of the metal being drawn,” Devine explains.

Benefits of ultrasonic tube drawing

“Adding ultrasonic energy to a tube-drawing operation can reduce the draw force required, in some cases by up to 35%, and permit heavier reductions thereby reducing the number of draws required to achieve a finished product,” Devine notes.

Additionally, ultrasonic tube drawing eliminates sticking and slipping, also known as “chatter,” which can lead to product loss. There’s less breakage, especially at start-up when frictional forces are highest. Draw speed can be increased as much as 400%. Most significantly – especially for medical applications – surface finishes on the ID of the tube can be improved to RMS (root mean square) values of 8 or better micro-inches.

Medical product applications

Sonobond Ultrasonics’ Tube Drawing System achieves superior tubing suitable for syringe needles and other sharps. Ultrasonically drawn fine tubing can also be used to produce implantable device components; in vitro diagnostic probes; bands for catheters and guidewires; heat-exchanger tubes for controlling blood temperature during surgery; micro-surgical tools; stents and other devices requiring tubing with a fine internal dimension finish.

Source: Sonobond

Latest from Today's Medical Developments

- Join our editors for a look at the manufacturing industry in 2025

- Surface Roughness, Texture, and Tribology Short Course

- There’s still time to register for our January 22 additive manufacturing webinar!

- EMO: Made for game changers

- Thomson’s encoder options for stepper motor linear actuator online selection tool

- BD boosts US manufacturing of critical medical devices

- Aerotech’s HexGen HEX150-125HL miniature hexapod

- World-leading medical device supplier via a new merger