The Marathon bombing brought prosthetics to the attention of millions of people – not only in the greater Boston area, but also around the world. On that day, 16 people lost limbs. Yet, because it was an attack on civilians on American soil and because some of those victims were children, we felt the impact of their loss on a more personal basis because we cared about what their future might hold.

The Marathon bombing brought prosthetics to the attention of millions of people – not only in the greater Boston area, but also around the world. On that day, 16 people lost limbs. Yet, because it was an attack on civilians on American soil and because some of those victims were children, we felt the impact of their loss on a more personal basis because we cared about what their future might hold.

For many of the luckier victims that future meant prosthetics.

Yet most people, unless they have had some sort of personal involvement with prosthetics, do not know much about them or what a life wearing one means.

We have seen an Olympic athlete run with two artificial limbs. Is that kind of mobility normal for everyone who has an artificial limb? What kind of maintenance is required with an artificial limb? How many prosthetic limbs will one person need over the course of his or her life?

The conflicts in Iraq and Afghanistan, have spurred advances in the construction and the quality of prosthetics. One of the byproducts from the Marathon tragedy was increased awareness of how far the science has come.

Archaeologists can date prosthetic care back to ancient Egypt. The first known written reference to an artificial limb was made around 500 B.C. when Herodotus wrote of a prisoner who escaped from his chains by cutting off his foot, which he later replaced with a wooden substitute. In 1858 in Capri, Italy, archaeologists also unearthed an artificial leg made of copper and wood dating from 300 B.C.

The major advancements in prosthetics have occurred during the past 150 years, most significantly with Dr. Giuliano Vanghetti’s invention of an artificial limb that could move through muscle contraction in 1898. Other advances included suction sock for above-the-knee prosthesis (1946) and later prosthetics that did not seek to replicate the natural limb but focused on lighter weights to facilitate acceleration and deceleration and reduce friction.

Component developments

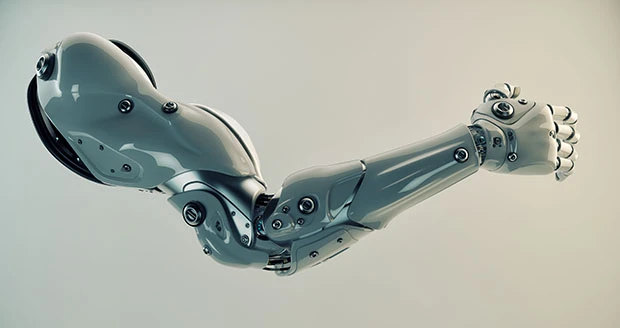

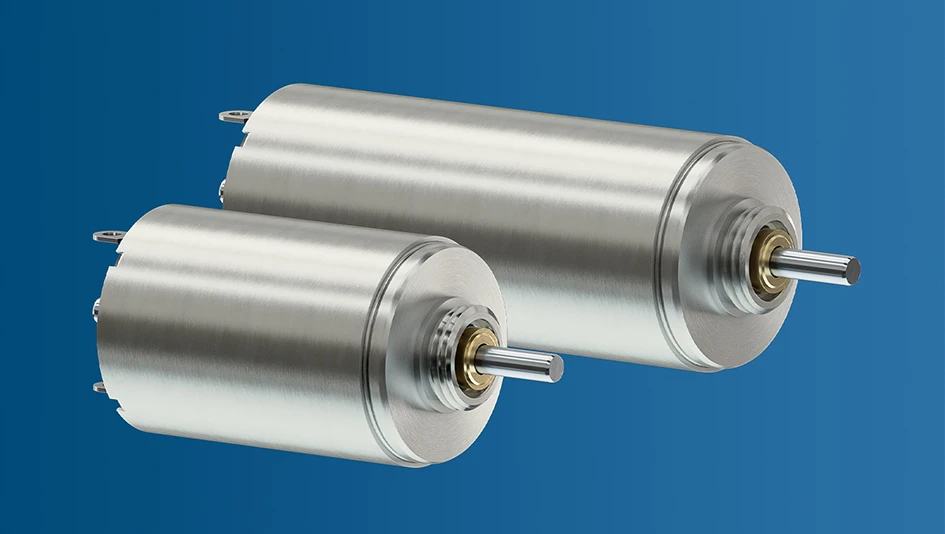

Ball bearings have been a central part of the design of prosthetic arms, hands, legs, and feet since the 1970s. During the past 15 years, the designs have become more dramatic and dynamic in design and application.

Ball bearings of varying styles are used to provide rotation and stability to help replicate normal movement of the joints and skeleton. Just as prosthetics have continued to evolve, so have the ball bearings used in them.

In recent years, design engineers have begun specifying many ball bearings that have traditionally been used in the aircraft industry, like the B500 series. These ball bearings have high load factors in a very slim, compact design.

The use of specialty plastic bushings also has created opportunities for innovative designs because of their durability. Plastic bushings can withstand exposure to dirty, high-load, or high-temperature applications and other things that a prosthetic might never have to withstand.

People who need prosthetics come in all sizes. Victims of the Boston Marathon ranged in age from 40-year-old adults to 7-year-old Jane Richard. While it stands to reason the external portions of a prosthetic limb need adjusting to the size of the person, adjustments also must be made for the internal design.

Design considerations

What needs to be considered in the design of prosthetics as it pertains to ball bearings? The design of the envelope dimensions must be as compact as possible and still provide for high loads and offer rotation with rigidity so that the movement is the same each time with minimal unwanted motion.

One critical aspect in the design should be the cross section or width of the bearing so that it provides rigidity and does not allow flexing of the shaft being supported. Whenever possible, we recommend sealed or shielded bearings so that the lubricant can be contained and contamination cannot enter the bearing surfaces. This also applies to rod-end applications being used for articulation.

When using ball bearings in the design of a prosthetic, most questions center on fatigue life, wear resistance, high load capacity, rigidity, and long life. Generally, because speeds are relatively low, the ball bearings used for prosthetics will not reach their design life under normal circumstances.

The design of a prosthetic tests the mettle of a company that distributes ball bearings perhaps more than any other project. Because a prosthetic is designed for one person, we work with companies on a case-by-case basis and there’s far more involvement with design engineers than most clients.

Typically, we work with the design engineers who have a sense of the envelope dimensions and the loads they are trying to support and the rotational speed they are trying to accommodate. Fortunately, most applications can be satisfied from the basic catalog of bearings manufactured worldwide because they are manufactured in millimeter or inch increments. This allows for a tremendous amount of design flexibility. In addition, since there is a standard numbering system used by all of the major ball bearing manufacturers, it is easier to get the precise bearing for a particular prosthesis without special ordering.

As someone whose family has been in the ball bearing business since 1957, I am often asked where we get our greatest satisfaction. Without trying to speak for previous generations, my answer is always quite simple. Selling ball bearings puts you in the midst of modern-day miracles.

Those miracles – accomplished with ball bearings – may be used in a train traveling from Boston to Washington, D.C. in but a few hours; a wind turbine harnessing Mother Nature’s gift of wind and transforming it into power; and last, but certainly not least, being part of the solution to provide someone without a limb the opportunity to walk.

Emerson Bearing

www.emersonbearing.com

About the author: Steven Katz is the president of Emerson Bearing, a bearing company catering to OEM and MRO markets. For more information, call 617.782.1400 or email info@emersonbearing.com.