United Grinding

As I wrap up the work week and prepare to head West for sunny California I wanted to make sure you saw some of the recent news in the industry. Manufacturing is busy, companies cutting chips and making parts. And, if you haven’t had a chance to read the current issue of the magazine, make sure you take a look at it today. Have a great weekend and hopefully I’ll connect with some of you at M&DM West in Anaheim.

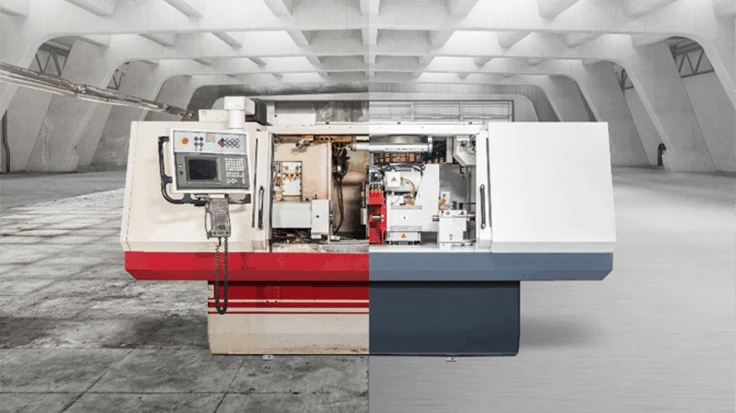

United Grinding rebuilds productivity life into 45,000hr machine

After 14 years in service, a Studer S40 grinding machine that had more than 45,000 hours of run time now produces precision components to tolerances it achieved when brand new. The Studer factory in Switzerland performed the rebuild that involved completely overhauling the machine, and while doing so, provided the machine’s owner LMT Kieninger with a loaner to ensure the customer’s production would continue uninterrupted.

A rebuild, or machine overhaul, makes sense not only economically, but also in the fact that operators continue to run a machine that is familiar to them for a seamless transition after the machine has been rebuilt.

Before (left) and after images of the equipment rebuild.

In the Studer factory, the rebuild specialists disassemble machines down to all their individual parts. The specialists completely refurbish guideways, overhaul the assemblies and replace all worn electrical cabinet components as well as all worn hydraulic and lubricating systems and valves. If spare parts are no longer available, Studer provides alternative solutions. For the final stages of the rebuild, the casting and components are sand-blasted and receive a fresh coat of paint. Once reassembled, the machine’s geometry is like that of a new machine.

"After our rebuild, we really noticed the difference,” says Heiko Braun, group manager of Cylindrical/Surface Grinding and Assembly at LMT Kieninger. “Since the overhaul, we have been grinding with the precision of a new machine. The rebuild process went without a hitch, and the investment has paid off because a 1,600mm grinder is worth its weight in gold for us."

If a customer wishes to expand a machine’s component range, the STUDER overhaul process can also include a retrofit during which a machine is modified to a customer’s particular requirements. This opens up new production possibilities on the same machine, which was the case with Ingold Tools AG.

Ingold Tools had been producing high-precision and complex parts for spindle, compressor, hydraulic and general machine manufacturing with 25 employees since 1946. Among its cylindrical grinders, the shop had an 18-year-old STUDER S21 with two external spindles and continuous fine adjustment of the turret wheelhead (B-axis fine).

Studer not only updated the S21 with the latest developments, but also retrofitted it to suit the needs of Ingold Tools AG. The cylindrical grinding machine now has an additional internal grinding spindle for internal cylindrical grinding and the relevant fixture for swiveling the tailstock into the park position. The machine also has a new spindle cooling system with its own circuit, as well as a hydraulically swiveling dressing unit. So that all grinding machines have the same mounting, the universal tool headstock was upgraded from MK4 to MK5.

According to Ingold Tools AG’s two managing directors Christoph Jenzer and Edgar Stich, the Studer retrofit resulted in them getting a second-hand machine with 50% new hardware.

Renishaw appoints Denis Zayia to role of president

Precision engineering and manufacturing technologies company Renishaw Inc. appointed Denis Zayia to president of its USA operations.

A 33-year industry veteran, Zayia started with Renishaw as coordinate measuring machine business manager in 1995 and became national sales manager for Industrial Metrology in 2008. His previous role was vice president sales and marketing, where he was responsible for Renishaw's line of industrial metrology and additive manufacturing products. He earned a Bachelor of Science degree in Electrical and Electronics Engineering from the University of Illinois at Chicago.

Zayia replaces Howard Salt, who, while turning over the responsibilities of day-to-day operations, will continue to provide valuable service to the organization as senior business manager Encoder Systems.

“Renishaw has been developing industry-changing products and end-to-end solutions for over 40 years,” Zayia says. “Our first product was a touch-trigger probe, which was developed to solve a manufacturing problem on Concorde engines. Today, we are helping manufacturers driven by the goals of Industry 4.0 with a wide range of technologies including additive, motion control, healthcare, spectroscopy, quality assurance and process control. I am incredibly excited about the opportunity to lead the organization through its next phase of growth.”

Guill offers medical machining, fabricating manufacturing services

Beyond being experts in extrusion tooling, Guill Tool and Engineering is a major industrial manufacturer providing medical machining, fabrication services. Guill offers 5-axis machining centers, high-precision machining, and full wire EDM capabilities with a 0.008” hole popper. Guill machines super alloys and exotic metals to close tolerances.

Guill CNC milling machines offer resources needed to successfully fulfill the most challenging parts and tooling to keep equipment running efficiently and precisely. The precision of CNC turning is offered for quicker production that meets rigorous standards, regardless of the complexity of the parts. Guill multi-axis machines can produce a variety of sizes, complex engineering and geometric intricacies. Prototype machining and rapid manufacturing enable engineering to develop and innovate solutions with the ability to respond and modify parts. Super alloys and other materials are offered to benefit customers who need new solutions to remain competitive. Finally, wire EDM eliminates the force put on part surfaces. This protects intricate and fragile tooling, as well as providing higher tolerances and accuracy.

Machining capabilities range from small hole machining to 0.008” in diameter and machining material measuring up to 15" in all axes.

Latest from Today's Medical Developments

- Application Park shows off diverse robotics applications

- Join our editors for a look at the manufacturing industry in 2025

- Surface Roughness, Texture, and Tribology Short Course

- There’s still time to register for our January 22 additive manufacturing webinar!

- EMO: Made for game changers

- Thomson’s encoder options for stepper motor linear actuator online selection tool

- BD boosts US manufacturing of critical medical devices

- Aerotech’s HexGen HEX150-125HL miniature hexapod