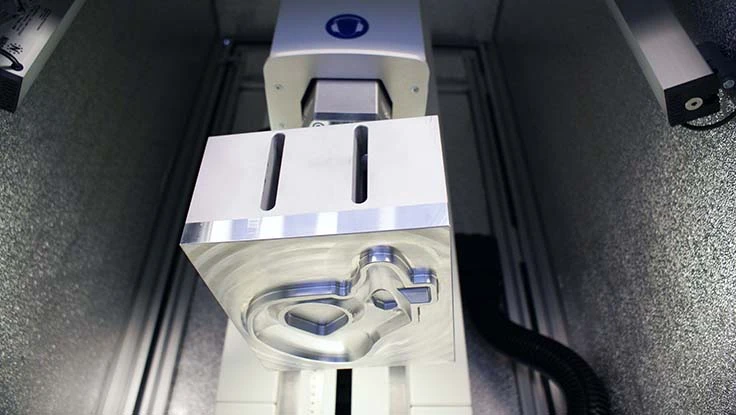

Bartlett, Illinois – Herrmann Ultrasonics Inc. has worked with medical company Genicon, in Winter Park, FL, to build one of the largest ultrasonic medical weld tools ever designed. The product being welded – a newly designed suction irrigation handle – which was shown by Genicon at the recent MEDICA 2015 tradeshow in Germany. The device in its entirety is used for liposuction. Due to the size of the joining partners and their three dimensional shape this application was very challenging – especially the 12mm difference in contour heights which needed to be matched by the contact surface of the weld tool, called sonotrode. The team at Herrmann made it work with a 220x180mm aluminum sonotrode.

Bartlett, Illinois – Herrmann Ultrasonics Inc. has worked with medical company Genicon, in Winter Park, FL, to build one of the largest ultrasonic medical weld tools ever designed. The product being welded – a newly designed suction irrigation handle – which was shown by Genicon at the recent MEDICA 2015 tradeshow in Germany. The device in its entirety is used for liposuction. Due to the size of the joining partners and their three dimensional shape this application was very challenging – especially the 12mm difference in contour heights which needed to be matched by the contact surface of the weld tool, called sonotrode. The team at Herrmann made it work with a 220x180mm aluminum sonotrode.

To meet the increasing requirements for ultrasonic assembly processes in sterile environments, Herrmann Ultrasonics has introduced the new MEDIALOG welder, which caters to medical device manufacturers. Together with stainless steel, cleanroom-friendly surfaces and modified pneumatics the MEDIALOG includes the unique operator interface FSC. This stands for FDA System Component and meets the demanding requirements FDA CFR 21 part 11 of the Food and Drug Administration. FSC includes a complete documentation all actions performed by authorized users and records time stamped audit trails. The creation of customized individual access authorization in combination with electronic signatures ensures authenticity, completeness, and confidentiality of all data.

To meet the increasing requirements for ultrasonic assembly processes in sterile environments, Herrmann Ultrasonics has introduced the new MEDIALOG welder, which caters to medical device manufacturers. Together with stainless steel, cleanroom-friendly surfaces and modified pneumatics the MEDIALOG includes the unique operator interface FSC. This stands for FDA System Component and meets the demanding requirements FDA CFR 21 part 11 of the Food and Drug Administration. FSC includes a complete documentation all actions performed by authorized users and records time stamped audit trails. The creation of customized individual access authorization in combination with electronic signatures ensures authenticity, completeness, and confidentiality of all data.

Source: Hermann Ultrasonics

Latest from Today's Medical Developments

- IMTS 2026 runs Sept. 14-19 at McCormick Place in Chicago, Illinois

- Master Bond’s MasterSil 800Med

- ZEISS celebrates 100 years of advancing innovation in the US

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out