For the past 14 years, NOVO Engineering’s creative, yet practical solutions have formed the basis for a variety of popular medical devices, life science automation, digital imaging equipment, and commercial products from clients such as Medtronic, Synthetic Genomics, Hewlett- Packard, and TaylorMade. NOVO engineers appear as inventors on a broad range of patents, with commercial rights usually assigned to clients. The company’s start-to-finish contract design service offers concept development, engineering, prototyping, fabrication, testing, and transition to manufacturing.

“We do a lot of prototyping and fabrication as part of our ISO-13485 certified product development process. We are not a contract manufacturer but are ISO-9001 certified for prototype builds including medical devices used for human clinical trials,” says NOVO President and Chief Technology Officer Dr. Rajan Ramaswamy. “We have helped many clients create stable designs, and then assisted them in transferring these designs to contract manufacturers all over the world.”

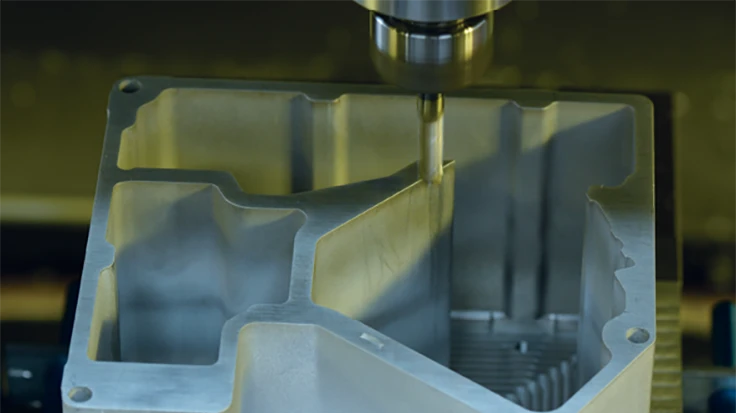

The company has a 26,000ft2 facility in Vista, California, and a 12,000ft2 design, testing lab, and prototype shop in Eden Prairie, Minnesota. The prototype shop offers CNC turning and milling, fused deposition modeling (FDM) and PolyJet 3D printing technologies and other processes including surface grinding and welding. More than 50 design engineers use SolidWorks as their primary 3D mechanical computer-aided design (MCAD) platform. Completed designs are submitted electronically via the company’s network to the machine shop for prototyping, and are directly imported into Mastercam, CAD/CAM software from CNC Software based in Tolland, Connecticut.

Doing more than others

Ramaswamy emphasizes that NOVO’s focus on research and development generates unique challenges and the team of engineers and machinists must take a methodical approach to tackling these projects.

“These parts are unusual, with complex geometries and tight tolerances, and careful planning of the machining activity is a big part of getting it all right,” he says. “Unique and one-off parts do not lend themselves to the speed and volume that traditional shops rely upon to turn a profit, but are a good fit for NOVO.”

Each of NOVO’s industry sectors generates different challenges. Drug delivery systems, such as wearable injectors, routinely use tiny components; scientific instruments require high precision or unusual materials; and optical devices rely on tight assembly tolerances. Engineers design parts in SolidWorks and transfer to Mastercam via the SolidWorks plug-in feature. Design changes are simple to make and don’t trigger extensive reprogramming.

“We do a lot of iterations of our parts, so if we make a change in SolidWorks, we can quickly pick it up in Mastercam and regenerate the model to create the new geometry. Mastercam will pick up the right code,” notes Leo Castellon, machinist at NOVO.

Toolpaths & complex geometries

Many of the parts NOVO engineers work on require tolerances within 0.002", on small features. For example, drilling 0.008" diameter holes through stainless steel or plastics.

“With medical devices, you’re working with parts where the hole diameter is frequently well below 0.040". Orders for some of the parts have us going through 0.120" of material with an 0.008" diameter hole,” Ramaswamy notes.

Frequently asked to innovate on parts fabrication, NOVO engineers collaborate directly with machinists to figure out design changes, fixturing, or machining changes that will help make a part feasible for fabrication. Mastercam’s toolpath selections offer more options to machinists on challenging parts.

Castellon explains that each machinist notes the required tolerances and geometries, designs any workpiece fixtures, sets up the CNC machines, machines the part, inspects it, and then releases it for assembly and testing.

“We use the Dynamic toolpaths because they’re so efficient in removing a large volume of material,” Castellon says.

Proprietary algorithms in the software intelligently detect changes in the geometry, allowing the tool to have greater engagement with the material for higher material removal rates. Machinists also find Mastercam’s 12+ plus surfacing toolpaths useful on complex parts because one toolpath typically can’t perform all the functions required. When machining plastic, the Dynamic toolpaths have often taken the machining time down from 10 min. to 30 sec.

“It’s much more efficient in the way it uses the tool,” Castellon says. “Plus, it’s much easier to program with Dynamic toolpaths – there is less geometry creation because they are intelligent.”

A frequent question Ramaswamy is asked is why they do not use 3D printing for all plastic parts. He responds that while NOVO uses 3D printing extensively, the technology “isn’t quite there yet” for creating many geometry/tolerance/material combinations required to prototype complex medical devices. In those cases, CNC machining is the preferred process.

Collaboration = success

The company’s environment might be fast-paced – needing to turn prototypes around quickly – but that doesn’t prevent machinists from experimenting to find the ideal formula for swift product delivery.

Castellon relies on his colleagues who have more than 30 years of experience working with heavy metals for the more traditional machining jobs, but he usually handles the more complex surfacing work. All the machinists do their own programming, setup, and machining from start to finish.

Machinists use tool libraries to create their own tools. For example one project required a 4" diameter end mill, so machinists created it in the tool library, imported it to ensure clearances were right, and verified that it met the application needs. The company rarely does repeat jobs, if an application is akin to something they have done before, machinists locate a similar tool in the library, regenerate the geometry, and Mastercam will pick it up.

“This is such a fast-paced environment. When we bring in a solid model, we need to have a finished part the next day. It has to be really efficient and Mastercam helps us with that,” Castellon says.

NOVO’s focus on innovation and customer service have made it the go-to partner for some of industry’s top companies when they need design, prototyping, and testing for complex electromechanical products. The company’s development process and seamless transfer of CAD designs into CAM software allows experimentation and creativity that’s proven to generate quality results.

This article originally appeared in the April 2017 issue of TMD.

Latest from Today's Medical Developments

- Siemens accelerates path toward AI-driven industries through innovation and partnerships

- REGO-FIX’s ForceMaster and powRgrip product lines

- Roundup of some news hires around the manufacturing industry

- Mazak’s INTEGREX j-Series NEO Machines

- The Association for Advancing Automation (A3) releases vision for a U.S. national robotics strategy

- Mitutoyo America’s SJ-220 Surftest

- #56 - Manufacturing Matters - How Robotics and Automation are Transforming Manufacturing

- STUDER looks back on a solid 2024 financial year