CREDIT: The Grainger College of Engineering at University of Illinois Urbana-Champaign

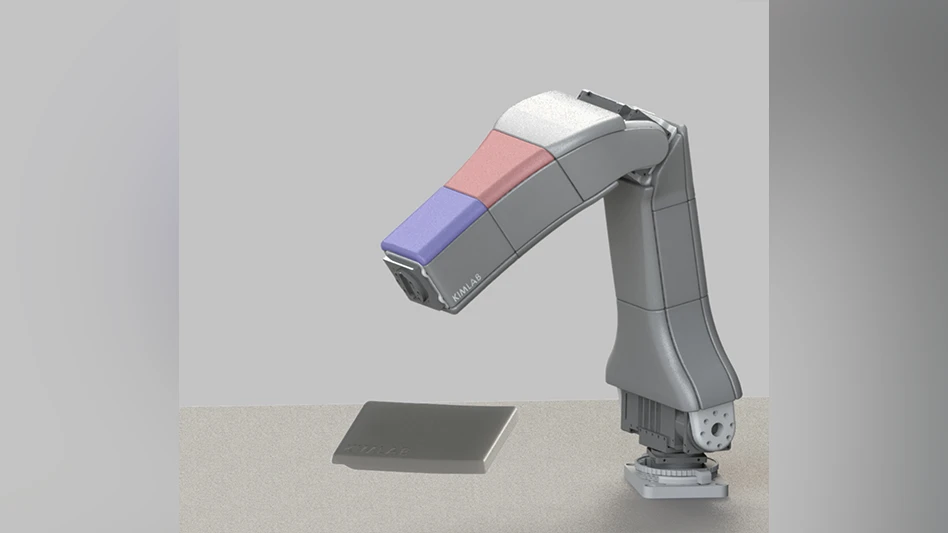

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult to make. A recent study demonstrates that soft skin pads doubling as sensors made from thermoplastic urethane can be efficiently manufactured using 3D printers.

“Robotic hardware can involve large forces and torques, so it needs to be made quite safe if it’s going to either directly interact with humans or be used in human environments,” says project lead Joohyung Kim, a professor of electrical & computer engineering at the University of Illinois Urbana-Champaign. “It’s expected that soft skin will play an important role in this regard since it can be used for both mechanical safety compliance and tactile sensing.

As reported in the journal IEEE Transactions on Robotics, the 3D-printed pads function as both soft skin for a robotic arm and pressure-based mechanical sensors. The pads have airtight seals and connect to pressure sensors. Like a squeezed balloon, the pad deforms when it touches something, and the displaced air activates the pressure sensor.

Kim explains, “Tactile robotic sensors usually contain very complicated arrays of electronics and are quite expensive, but we have shown that functional, durable alternatives can be made very cheaply. Moreover, since it’s just a question of reprogramming a 3D printer, the same technique can be easily customized to different robotic systems.”

The researchers demonstrated that this functionality can be naturally used for safety: if the pads detect anything near a dangerous area such as a joint, the arm automatically stops. They can also be used for operational functionality with the robot interpreting touches and taps as instructions.

Since 3D-printed parts are comparatively simple and inexpensive to manufacture, they can be easily adapted to new robotic systems and replaced. Kim noted that this feature is desirable in applications where cleaning and maintaining parts is expensive or infeasible.

“Imagine you want to use soft-skinned robots to assist in a hospital setting,” he says. “They would need to be regularly sanitized, or the skin would need to be regularly replaced. Either way,there’s a huge cost. However, 3D printing is a very scalable process, so interchangeable parts can be inexpensively made and easily snapped on and off the robot body.”

Tactile inputs like the kind provided by the new pads are a relatively unexplored facet of robotic sensing and control. Kim hopes that the ease of this new manufacturing technique will inspire more interest.

“Right now, computer vision and language models are the two major ways that humans can interact with robotic systems, but there is a need for more data on physical interactions, or ‘force-level’ data,” he says. “From the robot’s point of view, this information is the most direct interaction with its environment, but there are very few users – mostly researchers – who think about this. Collecting this force-level data is a target task for me and my group.

Kyungseo Park (Daegu Gyeongbuk Institute of Science and Technology), Kazuki Shin (NVIDIA), Sankalp Yamsani (Illinois) and Kevin Genehyub Gim (Boston Dynamics) also contributed to this work. All were affiliated with KIMLAB when the article was submitted.

The study, “Low-cost and Easy-to-Build Soft Robotic Skin for Safe and Contact-rich Human-Robot Collaboration,” is available online. DOI: 10.1109/TRO.2024.3378174

Support was provided by the Toyota Research Institute.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.