GF Machining Solutions

GF Machining Solutions has more than 60 years of experience building EDM machines, producing new, more efficient machines and providing new features on existing machines. Machines already installed on the field can benefit from several upgrades, allowing customers in different market segments to remain competitive in the future. Five possible upgrade types for the CUT C, E, and P EDM machine series will help customers improve productivity, enlarge the machines' functionality, reach higher autonomy, and ensure process safety.

More productivity after upgrade

The Turbo Tech upgrade improves processes. After the machine is upgraded, it has an additional technology priorities option, which is the perfect compromise between speed and accuracy – in good or bad flushing conditions. Productivity can increase from 10% to 40%, depending on the geometry of the part and flushing conditions. Turbo Tech is available on steel with different wire types, Ø 0.25mm (AC Brass, AC Cut VS+, AC Cut VH, and AC Cut AH) and AC Brass 0.20mm diameter.

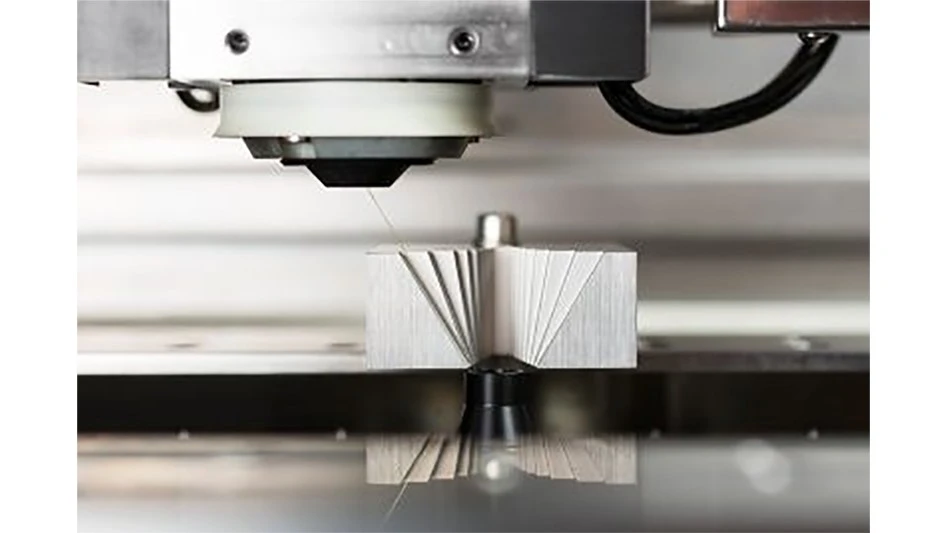

Enlarged machine functionality

If the need is to fulfil new market requirements, functional upgrades can be added to existing machine, such as the Taper Expert upgrade, designed for producing large taper parts or parts requiring small wire.

Improved production safety and longer lifetime of the equipment

An upgrade linked to Windows 10 allows customers to keep equipment running on the highest security level, reaching a new safety standard with the latest Microsoft license. Machines will remain up-to-date and benefit from future security developments, the latest software updates, and improvements, while staying connected to rConnect, GF Machining Solutions' digital solution designed for monitoring the status of the machine. If customers have multiple machines and upgrade them, their machine park will remain at the same operating level.

Improved connectivity and digitalization of production

GF Machining Solutions' rConnect platform consists of three digital services that make use of connectivity: rConnect Customer Cockpit, rConnect Live Remote Assistance, and rConnect Messenger. With secure rConnect Live Remote Assistance, customers benefit from the personal support of GF Machining Solutions' highly qualified experts, while the rConnect Messenger app allows them to gain remote access to their machines and receive status updates on mobile devices. The recently developed Seamless Support, a new module in Live Remote Assistance, enables customers to generate their service requests or ask their questions about applications directly from their control system.

Higher machining autonomy

Customers can enlarge the autonomy of their machines by increasing the working time without human intervention. One example is the big spool upgrade (for up to 25kg wire), which ensures a longer process continuity with no need for constant change of the wire. By integrating an automated cell into their workflow, customers can even automate their whole process. With these upgrades, customers can modernize and add value to their existing wire-cutting EDM machines.

Success Packs

Success Packs maximize customers' return on investment and help them succeed across all industrial segments. While the À la carte services can include operational service interventions, advanced diagnosis, certification, upgrades, training, and financial solutions, the Success Packs are a comprehensive range of services that guarantee customers have the support they need for their respective challenges. The Success Packs are staggered into different levels: Bronze, Bronze+, Silver and Silver+.

The Silver Success Pack, which is dedicated to industrial players with fierce competition generating pressure on margins, will provide them with everything they need to increase the performance of their machines. In addition, it comprises an annually scheduled intervention on site, preferred pricing on parts and labor related to preventive maintenance, a certificate for customers using certified wear parts and maintenance services, and an innovative upgrade, such as the Turbo Tech upgrade.

Latest from Today's Medical Developments

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3