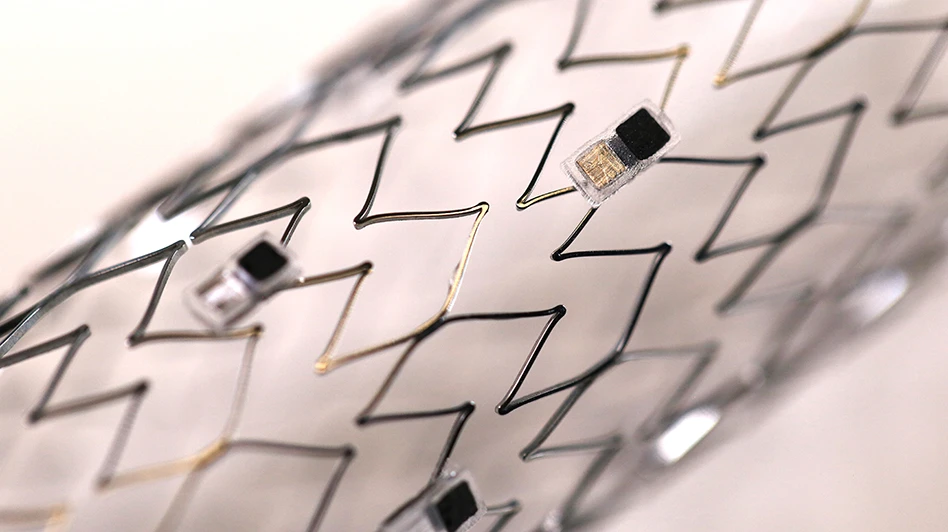

CREDIT: BOULDER IQ

To address medical device developers’ concerns about sterilization in the wake of the U.S. Environmental Protection Agency’s final ruling on ethylene oxide (EO) commercial sterilization, Boulder iQ is expanding its chlorine dioxide (CD) sterilization capacity.

Boulder Sterilization, a division of Boulder iQ, has converted another one of its EO chambers to CD. This smaller, 8-cubic-foot chamber is in addition to its existing 270-cubic-foot CD sterilizer. “Many developers are concerned about the future of EO after the EPA ruling,” says Jim Kasic, president and CEO of Boulder iQ. “Once they understand the benefits of CD sterilization, they are anxious to make the move.”

In April, the U.S. Environmental Protection Agency (EPA) issued a final rule that will put in place the strongest measures to date for EO commercial sterilization facilities] – a rule that will impact virtually all medical device contract sterilization companies, and that has the possibility to significantly decrease the supply of EO sterilization facilities and increase EO sterilization prices.

The chlorine dioxide alternative

“Medical device developers used to sterilizing with EO are understandably concerned about its viability and availability going forward,” Kasic says. While the EPA is not eliminating EO sterilization, but rather working to reduce EO exposure, he states that CD offers one of the best alternatives available. “It’s an effective, efficient, clean method of sterilization with a long and successful history,” he explains.

CD also is an environmentally friendly option appropriate for a majority of medical devices. It’s non-carcinogenic and nonflammable and has no post-treatment residuals. It can sterilize at room temperature, making it ideal for novel materials and plastics.

Safe EO sterilization

Boulder Sterilization will continue to operate six small EO chambers. “EO will still be the best sterilization choice for some products,” Kasic says. The company uses small, single-use EO canisters to provide simple, safe loading and unloading – eliminating the risks that come with large quantities of potentially dangerous-to-handle EO gas. The contract sterilization organization has also equipped its EO sterilizers with abators (catalytic converters) that reduce emissions by more than 99.9%, already in compliance with the new EPA standards.

“The options we offer, and the variety of CD chamber sizes, are allowing us to meet the market need for different volumes and sizes of product,” Kasic says. “Along with our fast-turn service – completing standard validations in as little as four weeks – we can help medical device developers get their products to market faster and more efficiently than ever with whatever type of sterilization works best for them.”

Latest from Today's Medical Developments

- Take control of your manufacturing business despite supply chain turmoil

- Strengthening the defense maritime industrial base for national security, economic resilience

- Hacker-proofing smart implants

- Register now to learn solutions for high-temperature aerospace machining challenges

- Expertise on machining, joining offered in April’s Manufacturing Lunch + Learn

- Incredible Machine works on the Rube Goldberg principle

- FAULHABER’s metal planetary gearhead family

- Aerospace Industry Outlook - Spring 2025, presented by Richard Aboulafia