Heraeus

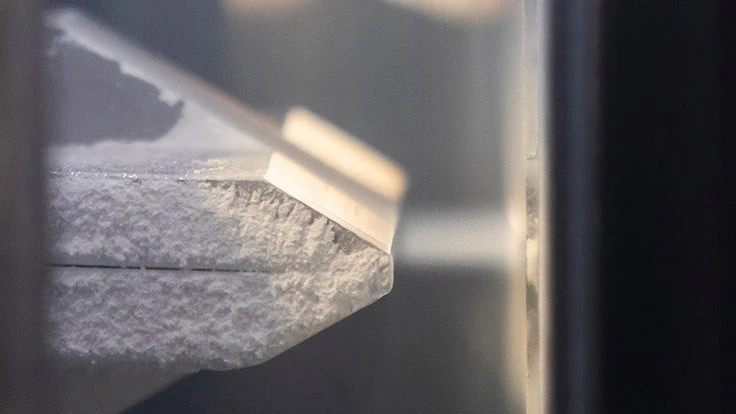

EOS Biomaterials Inc. relies on Heraeus R&D equipment to develop coatings for the medical market. The company’s technology can be used for surgical implants and wound treatment. Their patented coatings include antiseptic and antibiotic effects and enable a slow release of antibiotics. The powder formulations can be applied with the aerosol deposition method.

"With our own aerosol deposition machine, we will be able to test and optimize new materials and material combinations in even shorter cycles in the future," says Mr. Lee, chairman of EOS Biomaterials Incorporated.

There are numerous fields of application for antiseptic coatings in medical technology. For example, they can be applied on implants or medical instruments. They are usually made from an active metallic component - for example silver - and a carrier material such as ceramic. The larger the active surface, the higher the antiseptic effect. However, the right material ratio of active component and carrier material not only determines whether the coatings achieve the desired antiseptic effect. The raw material metal is also a cost driver. That's why manufacturers strive to identify the best mixing ratio.

heraeus-high-performance-coatings.com

Heraeus R&D equipment to develop coatings for the medical market.

"We already draw on Heraeus' materials expertise as part of a development contract. Our medical coatings experts receive powder development support with testing, analysis, and consulting," so Mr. Lee.

The equipment is built in Germany and shipped to EOS Biomaterials in New Taipei City. It allows coating of areas up to 300x50mm2 and axially symmetric items.

"The robustness of equipment and process makes aerosol deposition the ideal match for EOS Biomaterials´ development goals," says Ilka Luck, head of Heraeus High Performance Coatings. “They are working on very innovative products, and we are very happy to support them in this effort."

Why aerosol deposition?

To develop new coatings quickly, the method used needed to be as flexible and easy to handle as possible. However, most coating methods require high temperatures and are carried out under high vacuum. Aerosol Deposition, on the other hand, is carried out at room temperature and requires only rough vacuum. Also, no materials hazardous to health are used, which simplifies handling.

The high-performance coatings must not peel off from their substrate. The particularly good adhesion, in turn, is one of the outstanding properties of coatings produced with aerosol deposition. This is due to the substrate and the coating forming a chemical bond where they meet.

With other coating methods, the materials used must be heated or vaporized. These temperatures can cause changes in the material and thus in the material properties. In contrast, aerosol deposition takes place at room temperature. During deposition on the substrate, neither a chemical reaction nor a phase transformation occurs. Thus, the properties of the starting material are largely retained in the coating.

This isn’t the only challenge that aerosol deposition does not present in the first place. When several materials are combined, it increases the complexity of the coating process. The components - in this case metal and ceramic – often have very different properties. Due to different melting points, for example, they cannot be applied simultaneously using conventional methods, or only with great effort. Aerosol deposition allows coatings with any material and combinations of materials. The only requirement is that they are available as powder.

Latest from Today's Medical Developments

- Metabolic research uses Siemens gas analyzers to deliver results with 99.9999% resolutions

- Mazak’s SYNCREX 38/9 Swiss-type production turning machine

- Current economic and geopolitical realities demand decisive action

- Collaboration to advance pediatric medical technologies

- Guyson's TR-1000 Custom Vertical Blast System

- Intelligent data for the digital factory

- Edge Technologies' latest barfeeders

- Arterex expands again with acquisition of Adroit USA