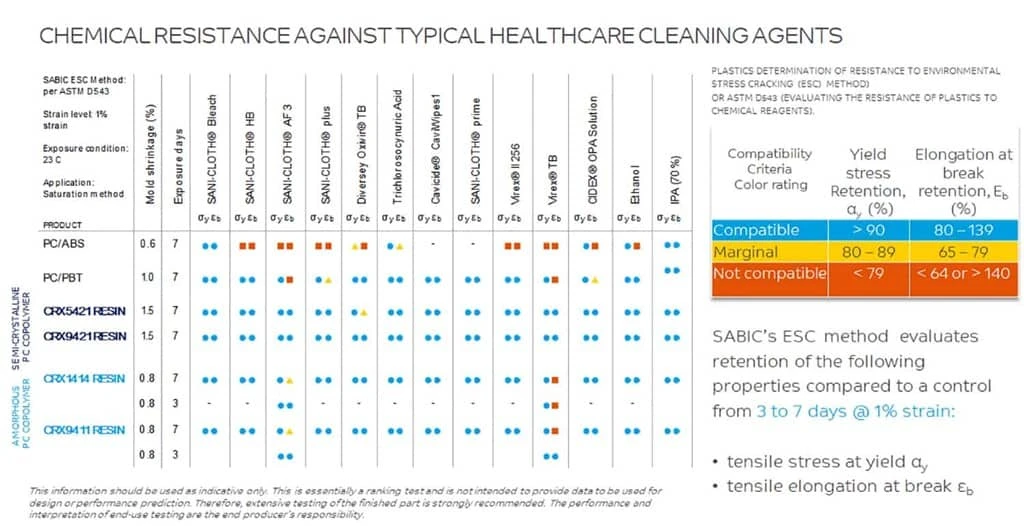

GRAPHICS COURTESY OF SABIC

According to the World Health Organization, healthcare-associated infections (HAIs) are the most frequent adverse event in care delivery worldwide. COVID-19 has prompted hospitals and clinics to increase protections against infection on top of the stringent sterilization and disinfection protocols already in place. Complicating this ongoing effort are the wide range of surface materials to be cleaned, more-frequent disinfection, and the use of harsh chemicals, which may be incompatible with traditional plastics.

Acrylonitrile-butadiene-styrene (ABS) and polycarbonate (PC) resins were traditionally used for medical device housings and enclosures. Chemical resistance became an issue, and components made with these materials started to fail from environmental stress cracking (ESC). So, manufacturers began replacing ABS and PC with blends of PC and ABS or polybutylene terephthalate (PBT).

Read the full article now!

Latest from Today's Medical Developments

- Stryker exiting spinal implant business

- Perfecting the manufacture of microscopically thin films for tech, medical applications

- Find out what 2025 holds for design and manufacturing

- Montagu to merge Tyber Medical, Intech and Resolve Surgical Technologies

- Americhem’s EcoLube MD PFAS-free internally lubricated compounds

- German robotics and automation in a downturn

- Blueshift’s AeroZero

- November USMTO grows from October 2024