Vollmer

"A passion for perfection" – for decades, this familiar quotation has stood for reliability and quality from VOLLMER in Biberach. It embodies the sustainable handling that, across generations, has turned the sharpening specialists into international technological leaders for machines for machining rotary tools as well as circular and band saws. Now, with the slogan "Sustainable sharpening. Because the future demands precision," the machine manufacturer is consolidating their sustainability, resting on seven pillars: Sustainable solutions. Real service. Loyal customers. Reliable suppliers. Loyal employees. An environment worth living in. Our company. Sustainable solutions. Real service. Two pillars stand for ideas and innovations We started with an idea – and Heinrich Vollmer had this idea in 1909, when he invented the first saw-setting and filing machine and founded his company. His vision of developing maximum sharpness for cutting tools and saw blades, is still being lived by at VOLLMER today. The machine manufacturer is therefore looking deeper into sustainable solutions rather than merely looking at the power consumption of a sharpening machine in watts. For machine developments, VOLLMER is therefore looking to service life, energy efficiency, automation, use of resources, digitalization, maintenance services, and reuse.

VOLLMER machines are equipped with numerous energy-saving features. But it’s about so much more – and one thing is certainly true: Products with a long service life and a high capacity for repair and recycling are economically sustainable. The realization is simple – the implementation is complex. The experiences that VOLLMER has gained from its 113-year history mean it can find the perfect interaction between materials, technologies, kinematics, automation, and services. VOLLMER machines are therefore in use by customers for a very long time. VOLLMER backs up their sustainable solutions with real services for maintenance, service, training, upgrades, or digitalization. These allow for a long service life and optimal operation and ensure that defective machines are quickly up and running again – or that they do not fail in the first place. VOLLMER achieves customer proximity thanks to subsidiaries in 14 countries across the world, as well as via digital V@dison solutions for holistic machine control. Using the Visual Support app, the web-based VOLLMER help desk can be integrated into the maintenance process, and spare parts that have been available for many years can, in future, be ordered any time by a customer via their personal digital customer portal. Loyal customers. Reliable suppliers. Loyal employees. Three of the pillars focus on people for VOLLMER, people are at the heart of sustainability, starting with VOLLMER's customers and their staff, right through to suppliers and partners in associations and organizations. This involves strengthening personal relationships over the long term and developing fair cooperation. VOLLMER is therefore a reliable partner to its customers where, for example, joint product developments are involved. When it comes to suppliers, VOLLMER relies on long-term partnerships and where possible, local procurement. Loyalty is the sustainable link that connects companies and employees. VOLLMER is proud to take on an above-average number of trainees and trains young people in technical and commercial professions. They offer flexible working hours, continuous further training, in-house health days, ergonomic workstations, or even leisure activities. The aim is to have a high retention rate for trainees – more often than not, employees remain with VOLLMER for their entire working life. Appreciating performance means that families often remain loyal to the company across generations.

An environment worth living in. Our company. Two pillars for a sustainable company VOLLMER always considers the economics from an ecological standpoint. An environment that is worth living in and one's own company are the factors that have a sustainable impact on the structure and culture. This includes energy-efficient manufacturing as well as the energy consumption for buildings or logistics. VOLLMER therefore ensures that packaging material, such as pallets or boxes, are produced in a sustainable manner. Sustainability also means taking responsibility for the workforce and the region. For the company, this means recognizing perspectives early on and being open to these. This not only applies for products and services, but also for the structure of the company. As a foundation, VOLLMER is secure in the long-term and will continue to be a reliable partner for customers, suppliers, and employees across generations. Furthermore, the Sieglinde Vollmer Foundation supports the training of young people and promotes projects that focus on STEM subjects – science, technology, engineering, and mathematics.

"With regard to supporting young people, we have already awarded the Sieglinde Vollmer Award on two occasions to young researchers who have engaged in STEM projects outside of school," says Dr Stefan Brand, CEO of the VOLLMER Group. "For us, people are at the heart of sustainability – they always have been and always will be the key to our tradition and our innovative strength!"

Latest from Today's Medical Developments

- Star Cutter incorporates TRU TECH brand into grinding technology portfolio

- WENZEL’s expanded LH CMM series

- Digital Transformation in 5-Axis Machining

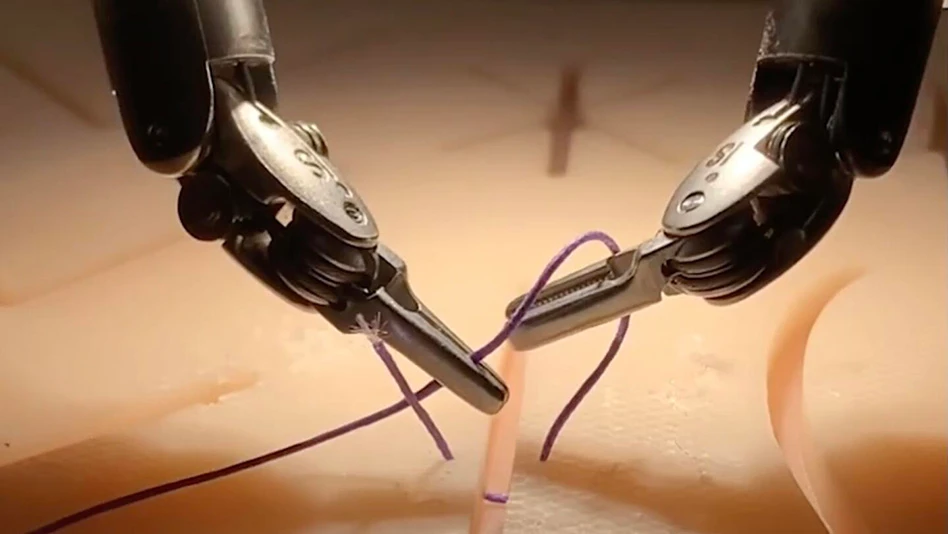

- Viant expands medical device solutions

- MIDACO’s automatic 4-pallet changer with trunnion system

- Breaking Free of the Additive Manufacturing Echo Chamber

- Boston Scientific to Acquire Cortex

- Don’t miss this month’s Manufacturing Lunch + Learn!