Guill Tool & Engineering

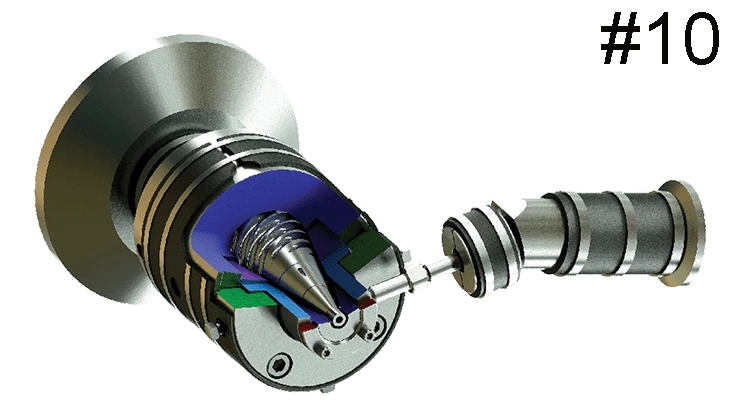

State-of-the-art production equipment and processes hold extremely close machining tolerances when producing multi-lumen and multi-layer medical tubing. However, tool misalignment or maintenance issues can produce exaggerated impacts on the final product.

Equipment maintenance

Improperly maintained equipment can waste 10% to 20% of the material, which can run from 50% to 90% of product cost, since in extrusion processes materials costs are typically higher than labor costs. Tooling suppliers go to great lengths to maintain tips and dies to a determined specification, ensuring perfect concentricity and alignment. Proper maintenance keeps it that way.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.