NIMS

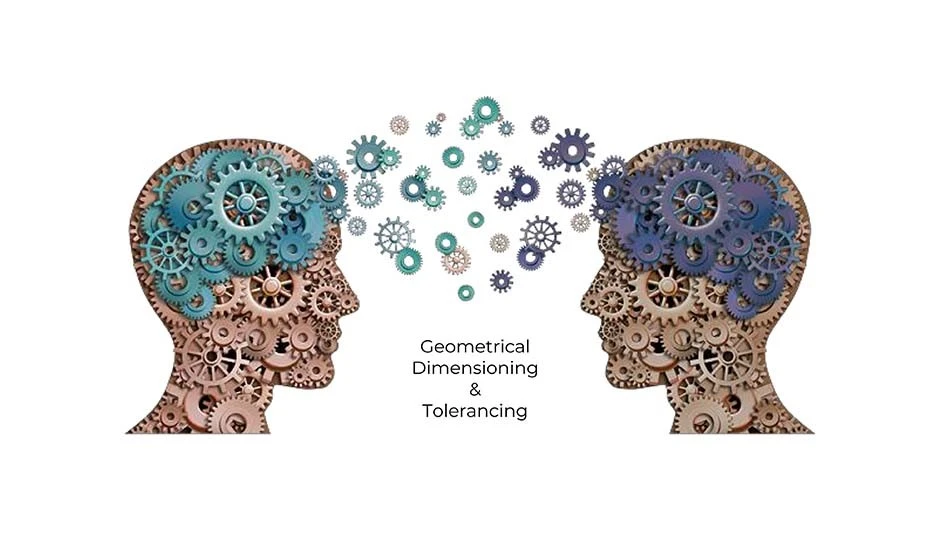

TheNational Institute for Metalworking Skills (NIMS) developed a new methodology to learn, retain, and transfer knowledge for geometric tolerancing & dimensioning (GDT) across an organization. NIMS offers the training in a day and a half workshop.

Most people are taught print reading with drawings annotated with limit dimensioning and all its flaws. Lessons in limit dimensioning are further applied in engineering or manufacturing activities, and then students or employees are exposed to GDT, the international standard with symbols to describe parts in a language that’s understood by any manufacturer. This traditional approach usually results in limit dimensioning being the first language, or native tongue, and GDT being the second. Going back and forth between the two is a struggle and may eventually lead to producing parts within the specifications but, according to NIMS, the approach is inconsistent and wastes time.

“GDT is the best way for manufacturers to ensure parts are absolutely within specifications,” said NIMS Executive Director Montez King. “It gives designers, engineers, and machinists a common language to communicate not only for manufacturing, but how those parts fit into its final assembly.”

However, like any language, it only works if everyone agrees to speak it and fully understands it. That’s where NIMS comes in.

According to King the optimal way to learn GDT is to teach employees and students how GDT works rather than its applications. Teaching GDT applications restricts understanding and only relays a process or procedure. When GDT is understood as though it’s the person’s native tongue, every application makes sense.

NIMS helps organizations transfer GDT knowledge and skills by teaching an organization how to embed GDT across all lines of communication. By the end of NIMS GDT training, staff can understand and use GDT in all stages of design and production.

Latest from Today's Medical Developments

- Costa Rica, a global magnet for medical devices

- PhD student helps develop medical device for children with congenital heart defects

- Happy New Year

- Best of 2024: #1 Article – 2024 Forecast

- Best of 2024: #1 News – 6 trends impact medtech in 2024

- Best of 2024: #2 Article – Cybersecurity in medical devices

- Best of 2024: #2 News – Miniaturized, implantable multi-sensors device to monitor vessels health

- Best of 2024: #3 Article – Intech Athens deploys ZOLLER tool management system to control tooling inventory