emodic@gie.net

When visiting machine tool builders throughout Europe, one key area always mentioned during a presentation about a company and its culture is what type of apprenticeship program they have. Apprenticeships are the norm throughout Europe, especially in Germany where the country’s vocational education and training system combines theoretical and practical learning – more than 1.3 million people are enrolled in apprenticeship training in Germany.

So, it was no surprise during a recent visit to INDEX factories and its headquarters in Germany that I heard from a young apprentice what she was training for and what makes up the program. At the time of my visit, the company had 136 people in the program – 126 trainees going through 1 to 3 years of training and 10 students. This month (September 2023), 46 new trainees are starting and 5 new students.

Cris Taylor, INDEX Corp.’s U.S. CEO – having started his career as a German apprentice – can’t boast enough about what a positive impact apprenticeship programs have on the industry. So, with an enthusiastic CEO, INDEX launched an eight-month apprenticeship program in January 2023 at its U.S. headquarters in Noblesville, Indiana. I recently checked in with Cris to see how it was going.

“It’s been fantastic. Our inaugural class has just wrapped up and our first 5 graduates head to Germany for 2 months this fall,” Cris says. “While there, they’ll each be responsible for building a machine, taking the lead in every aspect of production. This is an extremely important part of the process. INDEX makes the best lathes in the world, and we need the best-trained technicians to be able to service them. When they return from Germany, they’ll have demonstrated they know our technology inside and out.”

I asked Cris what the feedback from the students has been: “Overwhelmingly positive,” he notes. While a main focus of the program was providing an education on the technical elements of being a machine technician, Cris says he was pleasantly surprised to see how the program also fostered teamwork. “When we’re providing a solution to a customer, it’s vital we function as a team – within and across departments. We’ve seen participants in the program build strong relationships with each other and people in other departments that’ll be vital to their success – from employees in purchasing and spare parts to sales and applications.”

Success from apprenticeships isn’t just happening at INDEX. This month’s issue also includes a feature about Wells Technology and its CEO Andy Wells’ apprenticeship program (pg. 23). Wells Academy, a 501c3 educational program for disadvantaged Native American applicants interested in positive life change and certification in CNC manufacturing, is in its 18th year of training locals.

When asked how this success could inspire similar apprenticeships across the U.S., Andy views it this way, “I believe everybody has some skills. I encourage employers to try and bring those out of people, invest in the people… we in business must start getting more involved in helping our young people with education and job training.”

Since next month is known as National Manufacturing Month and October 6, 2023, as MFG Day, what are you doing to help support training the next generation that will keep the manufacturing sector humming along?

Explore the September 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

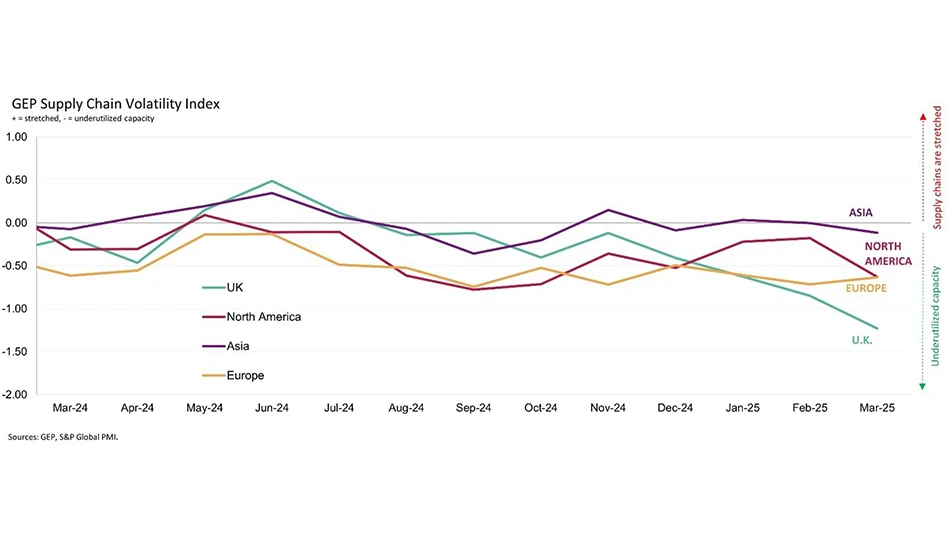

- Unlocking GenAI's potential: Insights from the Supply Chain Horizons 2025 report

- Celebrating 75 years of innovation at Jorgensen Conveyor and Filtration Solutions

- Free webinar to offer expert advice on optimizing machining operations

- How collaboration between companies can elevate manufacturing

- AI meets innovation: Cambridge's device transforms heart screening

- Mazak and Premier Engineering team up for greater agility in Florida

- Struggling with inventory or supply chain pressures? Find answers in our free webinar

- Free webinar: Advanced manufacturing solutions to support the Navy