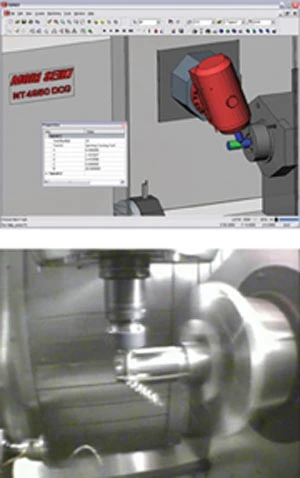

Newly created turning spinning-tool technology, developed jointly by Mori Seiki and Kennametal Inc, was used in the first successful test cut performed by DP Technology, creator of ESPRIT CAM software.

Designed to distribute heat and wear more effectively than a single-point lathe tool, the new turning spinning-tool technology can increase productivity by up to 500% and tool life by up to 2,000%. This cutting technology employs a specialized insert – similar in design to a round, or full-radius insert – mounted at the bottom of a cylindrical tool shank held in a rotary spindle.

"This technology is promising because of all the advantages it provides," says Olivier Thenoz, DP's mill-turn product manager. "In the end, it means better productivity."

Thenoz teamed up with Nitin Chaphalkar, engineering team leader for Mori Seiki's Machining Technology Laboratory (MTL) at the company's Chicago Technical Center last month to perform the cut. The test included roughing and finishing operations on the outer diameter (OD) with a Mori Seiki NT4200. The full capabilities of the turning spinning tool were put to the test with OD passes on straights, tapers and arcs without the use of coolant on the steel workpiece.

"The advantage of the spinning tool is that there is no one single point on the tool that is in contact with the work piece all the time," Thenoz says, "and this is very good for heat dissipation and tool wear. Cutting conditions are no longer limited by the heat generated in the process, but by power available in the machine."

"Cutting forces generated while machining with single-point tools impart a bending movement on the tool and give rise to vibrations," Chaphalkar says, explaining the potential benefits of an axially loaded tool. "In the case of axially loaded tools, such as a spinning tool, most of the cutting forces are directed axially into the spindle and hence significantly reduce vibrations. The point of this tool is to reduce vibration and chatter, and to increase tool life and productivity."

For the initial OD rough cut, the spinning tool was inclined at a 20o angle, which, according to research conducted by MTL, is the angle that allows the most effective heat evacuation for this application. The turning spinning tool is also well adapted to cutting in a back-and-forth motion, and this capability was also put to the test on taper and arc moves – with impressive results. The tool remained close to the material throughout the cut, and the repositioning moves necessary with the use of single-point tools cutting in a single direction were not required.

According to Chaphalkar, Kennametal pioneered the foundations of the turning spinning tool. Mori Seiki continued development, and took its version of the tool into several CAM companies to solicit a solution for the new technology.

After being contacted by Mori Seiki in October, 2007, DP Technology became the only CAM company that demonstrated that it was able to take on the challenge, and the ESPRIT Turning Spinning Tool Add-In was complete by the end of November.

Chaphalkar says that, while he was able to program basic functions by hand, the ESPRIT Turning Spinning Tool Add-In is the right solution for making the most of the tool.

"With ESPRIT, the programming complexities are made easier and customers will be able to use the technology efficiently," he says.

Thenoz said that developing for ease-of-use, while making the most of new technology means better results for end users with diverse needs.

"We are looking for new programming challenges and are trying to stay ahead of all the new cutting technology," Thenoz says. "We have shown that before, with the new B-axis turning, and this is a continuation of that philosophy. We want advanced functionalities and, at the same time, functionalities for everyone."

Mori Seiki plans to employ the new turning spinning tool technology in Japan for "our own manufacturing operations," Chaphalkar says. The technology was exhibited at the Mori Seiki open house in Chicago this month, in addition to the ESPRIT World Conference 2008, and will also be shown at IMTS 2008, JIMTOF 2008, and EMO 2009 shows.

"It's a great partnership with Mori Seiki," Thenoz says of the development of the turning spinning-tool technology. "It's important for us to be involved in this project and to have the opportunity to perform test cuts like this one."

Turning Spinning Tool Add-In

The ESPRIT Turning Spinning Tool Add-In makes it easy to use Mori Seiki's spinning tool technology. The add-in provides a new interface to define the size and shape of the tool being used and adds new machining technology parameters to all standard turning operations in ESPRIT that let the user define the rotation speed of the tool spindle and the angle of inclination for the cutting plane.

For spinning tool turning operations, it is typical to set the tool spindle and turning spindles to the same revolutions per minute (rpm). The user has the option of creating the toolpath in +Y or –Y in the YZ plane, and also has the ability to rotate the cutting plane about the Z axis to allow machining above or below the center line. The tilt of the tool is handled using a standard parameter available for any ESPRIT turning operation. ESPRIT supports full simulation of the cutting path with collision detection. The add-in also includes updated post processors for Mori Seiki machines.

Explore the May 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module