The miniature M3-F focus module is currently in production in commercial camera systems for biometric identification, medical devices, and various machine vision applications by leading OEMs in these markets. More than 50 OEM additional customers have completed qualification of the M3-F focus module in vision systems, slated to go into volume production during the next six months.

The miniature M3-F focus module is currently in production in commercial camera systems for biometric identification, medical devices, and various machine vision applications by leading OEMs in these markets. More than 50 OEM additional customers have completed qualification of the M3-F focus module in vision systems, slated to go into volume production during the next six months.

The ability to adjust focus through the use of software is increasingly a high-priority feature in compact cameras. This is especially true for applications requiring high image quality along with fast and automatic image capture, such as biometric detection and medical devices. The widespread adoption of the M3-F validates its performance advantage and the ease with which it can integrate into OEM board camera systems.

New Scale and its OEM customers worked closely with precision lens manufacturer Sunex on a large number of these projects, receiving assistance with lens specification and optical system design.

In biometric identification, the M3-F focus module improves usability by enabling image capture across a greater depth of field, typically about 1" to infinity depending on the lens. This makes it easier to position the eye in front of a biometric ID camera, resulting in a more accurate iris, face, or fingerprint match, and with less time and effort on the part of the user.

In medical diagnostic systems, the M3-F focus module enables faster and more accurate sample analysis, alleviating the need for highly meticulous sample positioning. In addition, it improves usability of medical devices, such as endoscopic imaging, by reducing the amount of time required to align the scope.

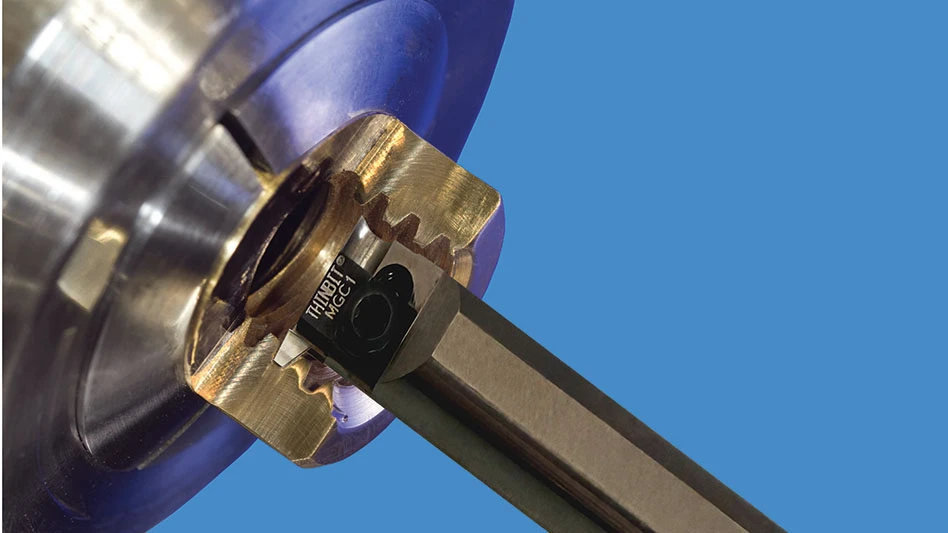

The M3-F adds flexibility to machine vision systems, allowing them to image a wider variety of parts without regard to their exact distance from the camera, and to image parts that have significant variations in depth.

The M3-F adds flexibility to machine vision systems, allowing them to image a wider variety of parts without regard to their exact distance from the camera, and to image parts that have significant variations in depth.

With a footprint of 20mm x 22mm, a height of 16mm, and no external control board, the M3-F easily replaces fixed lens holders over CCD or CMOS image sensors, without adding to the camera size. It is compatible with image sensors up to 17mm x 17mm, including the 1/2" and 1-1/8" formats.

The M3-F accepts high-quality glass or polymer lenses, which have greater transmission and clarity than non-traditional composite lenses of liquid or liquid crystal. It accepts standard threaded lens assemblies from M8 to M12 in size, and up to 5g in weight.

The M3-F moves lenses with 0.5µ position resolution and very low tip/tilt, keeping the image focused on the center of the image sensor. The embedded closed-loop drive delivers high repeatability, low temperature dependence, and no hysteresis.

Explore the November December 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system

- US cutting tools orders decreased 2% from November 2024

- SMW Autoblok's Manual Jack connection kit

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business