Many people talk about cutting their teeth in a certain business as a way of referring to how they have learned a skill or trade from the ground up.

Many people talk about cutting their teeth in a certain business as a way of referring to how they have learned a skill or trade from the ground up.

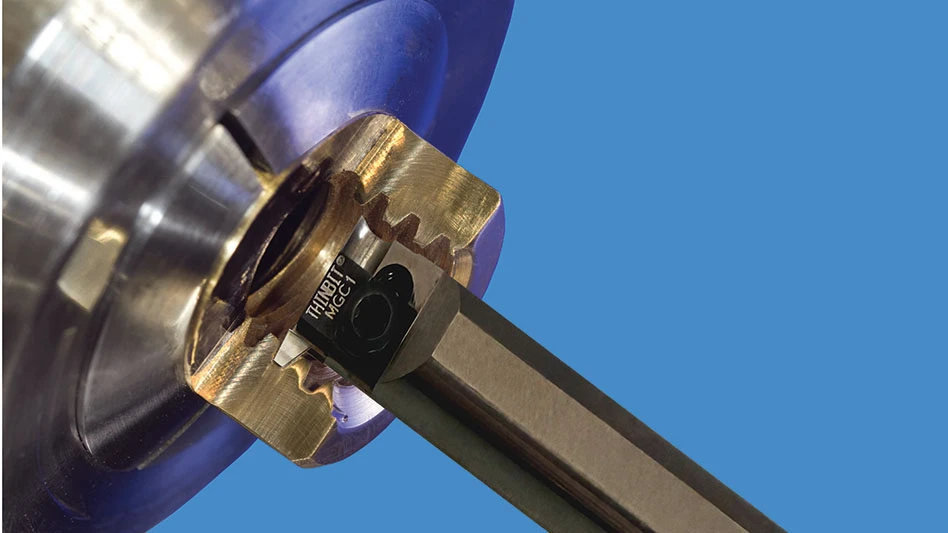

For Marc Stipo, president, High Point Precision Products Inc., Sussex, NJ, this expression has a slightly more literal meaning. In honing his company's offerings for the medical device arena – including for dental, orthopedic implant, and surgical instrumentation applications – Stipo has literally cut into cadaver teeth. Beyond the cadaver teeth he has also cut into cow bones – that he gets from a local butcher – in order to help his customers understand just how well the parts he is making for them will perform.

"We bring a lot of unique knowledge to the table," Stipo says, explaining how his company helps provide its customers with unique, money saving solutions for producing their medical devices. "Recently we were making some prototype surgical tooling. After getting the prints and making some parts, we spoke to the engineer designing the parts. I said to him 'Why not develop the cutting tool here? We can go to the butcher and get some bone to mimic the surgical process you are trying to achieve and refine the part right here in our shop.'"

It is the combination of unique knowledge and old-fashioned customer service that has helped this 15-man company grow, out of Stipo's father's basement in Northern New Jersey, into a leading job shop serving the medical device market. While High Point Precision Products is not the biggest player in medical device manufacturing, it does seek to rely on innovative machine tool and CAD/CAM technology to provide unique, cost effective part manufacturing solutions. To this point, the company employs seven multi-axis CNC Swiss-type lathes including a variety of Citizen L, K, and M series models, a Star SA, and two Haas vertical machining centers. In order to be competitive, and provide its customers with fast turnaround and the shortest possible lead times on complex medical devices, High Point Precision Products programs all of the machines with Delcam's PartMaker CAM software.

"In today's medical device industry, engineers are using CAD to the fullest of its capabilities, which means part geometries are getting more complicated," Stipo says. "As a result, there have been countless jobs we just would not have been able to produce without PartMaker."

Marc Stipo has literally cut into cadaver teeth. Beyond the cadaver he has cut into cow bones – he gets from a local butcher – in order to help his customers understand just how well the parts he is making for them perform. Marc Stipo has literally cut into cadaver teeth. Beyond the cadaver he has cut into cow bones – he gets from a local butcher – in order to help his customers understand just how well the parts he is making for them perform. |

Machines, Programming

From a machine tool perspective, High Point Precision Products' mix of machines leans heavily toward complex Swiss-type lathes, although it certainly has ample milling capability. The CNC mills in use at High Point Precision Products range in cost from $50,000 to $60,000 whereas the Swiss machines generally cost $250,000 to $300,000 each. As such, the Swiss machines have a much higher opportunity cost of capital, so it is paramount that they stay running as much as possible, no matter the lot size.

To help outsiders better understand the cost of investing in Swiss machines versus mills, Stipo draws an analogy between cars and houses.

"In terms people can understand: The price point of buying a typical milling machine, costing $50,000 to $60,000, with five to seven years to pay it off, is like buying a car. That does not seem so bad," Stipo says. "When you buy a CNC Swiss-type lathe – costing $250,000 to $300,000 – it is like buying a house and paying it off in five to seven years. As a result, Swiss machines have to be able to produce at a high hourly rate to justify their cost."

According Stipo, the best way to achieve this is to make very technically demanding, complex parts, which is exactly where PartMaker software helps. PartMaker software helps the engineers at High Point Precision Products program parts that are more complex. The software allows the engineers to program faster and in a more automated fashion, which in turn leads to fewer errors on the shop floor. Getting programming of a part right, the first time – even for the company's complex array of Swiss machines – enables faster setup times and shorter lead times for High Point Precision Products' customers.

"We do not get paid while we are setting up or even running our machine. We get paid when the parts are done and shipped to the customer," Stipo explains. "Being a contract manufacturer is not like being a building contractor where you get paid as jobs moves along to completion, you only get paid after the job has been done successfully, so we need to make sure to get jobs turned around as fast as possible."

"We do not get paid while we are setting up or even running our machine. We get paid when the parts are done and shipped to the customer," Stipo explains. "Being a contract manufacturer is not like being a building contractor where you get paid as jobs moves along to completion, you only get paid after the job has been done successfully, so we need to make sure to get jobs turned around as fast as possible."

Although High Point Precision Products is a rather small shop, they are able to compete with much larger outfits based on the skill of their staff and the sophistication of their technology. As Stipo sees it, even in very large machining organizations, there might only be three of four individuals who really have an in depth knowledge of part processing. According to Stipo, what this leads to is a situation where knowledge becomes defuse across an organization and these individuals become spread very thin.

Focusing the unique talents of a small group on a customer's problems enables High Point Precision Products to stay a step ahead. It allows Stipo and his team to come up with practical cost saving ideas, like testing on animal bones for surgical tools or cadaver teeth for dental implants. All such testing occurs in an area sequestered from the shop floor, such that there is no possible risk of contagion with the production floor.

Being smaller also enhances the need for diversification among his customer base. Implementing a CAM system that allows for the quick programming and turn-around of parts, allows High Point Precision Products to satisfy a diverse customer base across a relatively small number of machines without running into capacity problems.

The Swiss machines in use at High Point Precision Products have upwards of 11 programmable axes, a level of complexity their CAM system must take into account. Delcam's PartMaker manages this complexity through the application of two patented technologies for automating the programming of multi-axis Swiss-type lathes. These technologies include the Divide and Conquer programming approach for programming parts with a number of turned and milled features. With all the advanced milling High Point Precision Products is doing on its medical parts, the ability to program the various milling functionality of its Swiss machines is critical. The second technology in PartMaker that Stipo's firm is able to take advantage of is the software's Visual Synchronization approach, which allows simultaneous machining processes to be synchronized, quickly and easily.

"PartMaker allows you to quickly see where you have excess spindle waiting time so we can make sure our part cycle times are optimized before sending a program to the machine," Stipo explains. "Having the ability to run what-if scenarios off-line saves machine time and assures our customers the best possible price for their products."

Prototyping for Success

High Point Precision Products works with a number of smaller, start-up medical device manufacturers. Stipo finds that such customers are receptive to the sort of experience and counsel that his company has to offer. By taking a hands-on approach with these customers, Stipo is able to reduce their product development cycle from months to weeks, by moving some the iterative work involved in prototyping and product development out of the customer's R&D lab to High Point Precision's facility.

"We have actually done tests on customers' parts on our shop floor and presented the information about which part designs perform the best," Stipo explains. "To design a part on a computer, and then have us make it to then try it out in an R&D lab can be very time consuming. When you are at the machine, making these changes can just be a couple of key strokes, or a quick change in PartMaker. The reality for our customers is that they are not making any money unless they have product out on the market. Working collaboratively with them like this can also make the machining easier and bring their costs down even further."

High Point Precision Products Inc. Sussex, NJ

highpointprecision.com

PartMaker Inc. A Div. of Delcam plc Ft. Washington, PA

partmaker.com

Explore the November December 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system

- US cutting tools orders decreased 2% from November 2024

- SMW Autoblok's Manual Jack connection kit

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business