Five Fraunhofer-institutes joined forces in 2009 to come up with biocompatible artificial blood vessels, through the BioRap project. It seemed impossible to build structures such as capillary vessels that are so small and complex, especially the branches and spaces, which makes life difficult for the researchers. However, production engineering came to the rescue because rapid prototyping makes it possible to build workpieces specific to any complex 3D model. Scientists at Fraunhofer are working on transferring this technology to the generation of tiny biomaterial structures by combining two different techniques: the 3D printing technology established in rapid prototyping and multi-photon polymerization developed in polymer science.

Five Fraunhofer-institutes joined forces in 2009 to come up with biocompatible artificial blood vessels, through the BioRap project. It seemed impossible to build structures such as capillary vessels that are so small and complex, especially the branches and spaces, which makes life difficult for the researchers. However, production engineering came to the rescue because rapid prototyping makes it possible to build workpieces specific to any complex 3D model. Scientists at Fraunhofer are working on transferring this technology to the generation of tiny biomaterial structures by combining two different techniques: the 3D printing technology established in rapid prototyping and multi-photon polymerization developed in polymer science.

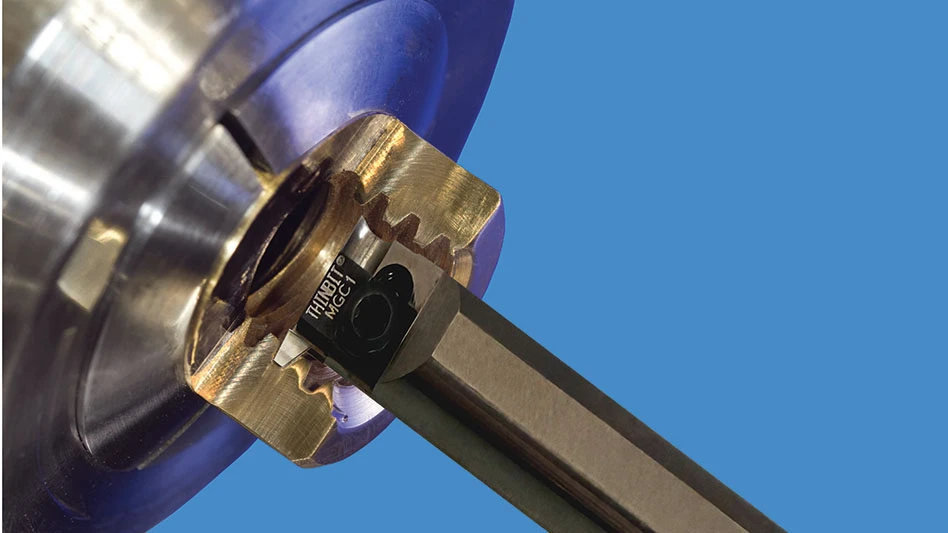

A 3D inkjet printer can generate 3D solids from a wide variety of materials very quickly. It applies the material in layers of defined shape, which chemically-bond by UV radiation. This creates micro-structures, but 3D printing technology is still too imprecise for the fine structures of capillary vessels. This is why these researchers combine this technology with two-photon polymerization. Brief, but intensive laser impulses impact the material and stimulate the molecules in a very small focus point so that crosslinking of the molecules occurs.

Dr. Günter Tovar, project manager at the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB based, Stuttgart, Germany, explains that, "The individual techniques are already functioning and they are presently working in the test phase; the prototype for the combined system is being built."

You have to have the right material to manufacture 3D elastic solids. This is the reason why the researchers came up with special inks, because printing technology itself calls for very specific properties. The later blood vessels have to be flexible and elastic, and interact with the natural tissue. Therefore, the synthetic tubes are bio-functionalized so that living body cells can dock onto them. The scientists integrate modified biomolecules – such as heparin and anchor peptides – into the inside walls. They also develop inks made of hybrid materials that contain a mixture of synthetic polymers and biomolecules right from the beginning. The second step is where endothelial cells, that form the innermost wall layer of each vessel in the body, can attach themselves in the tube systems.

The virtual simulation of the finished workpieces is just as significant for project success as the new materials and production techniques. Researchers have to calculate, precisely, the design of these structures and the course of the vascular systems to ensure optimum flow speeds while preventing back-ups. The scientists at Fraunhofer are still at the dawn of this entirely new technology, although this technology offers a whole series of opportunities for further development.

One example would be building up completely artificial organs based on a circulation system with blood vessels created in this fashion to supply them with nutrients. They are still not suited for transplantations, but the complexes of organs are usable as a test system to replace animal experiments.

This is a project that the Fraunhofer Institute for Applied Polymer Research IAP, Potsdam, Germany; the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart, Germany; the Fraunhofer Institute for Laser Technology ILT, Aachen, Germany; the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Stuttgart, Germany; and the Fraunhofer Institute for Material Mechanics IWM, Freiburg, Germany are all participating in together.

Explore the November December 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system

- US cutting tools orders decreased 2% from November 2024

- SMW Autoblok's Manual Jack connection kit

- MedTech Innovator welcomes five new industry partners

- First Article Inspection for quality control

- The manufacturing resurgence is here – are you ready?

- Workholding solutions for your business