Mikrotech is a leading ISO-certified micro manufacturer of custom-designed components and subassemblies for medical devices used in minimally invasive surgery (MIS). Mikrotech offers a comprehensive range of services to support MIS designers and manufacturers in all phases of the product development cycle, including micro-machining, micro-molding, insert micro-molding, micro-subassembly, and plastic design and manufacturing engineering assistance.

The company’s micro-manufacturing processes overcome the limitations of established technologies, facilitating smaller components with complex features and high-precision tolerances.

Mikrotech offers multi-axis and Swiss screw micro-machining for prototype and short-run production. Mikrotech has the capability of micro-machining high-performance plastics such as ABS, PEEK, PAI (Torlon), PPS, PEI, PTFE, and glass-filled materials including LCP and PEI (Ultem).

Mikrotech has an experienced engineering team with a focused understanding of medical devices used in MIS. Engineers have the ability to help reduce the complexity of manufacturing MIS devices through the process of reducing or eliminating processes that: 1) use expensive machined components; 2) require highly skilled labor (artisans) using a microscope; and 3) require complex secondary operations to assemble them.

Micro-manufacturing technology can be an excellent lower-cost alternative to designing and manufacturing components and subassemblies for MIS devices.

Capabilities/Equipment/Software

- Twice the precision and repeatability of conventional molding equipment

- Can accurately mold components weighing less than 0.1g (0.0035oz)

- Capable of micro-molding high-performance plastics such as LCP, PC, PEEK, PEI, PPS, and PSU

- Dimensional tolerances of ±0.005mm (0.0002")

- Maintain wall thicknesses as low as 0.08mm (0.003")

- Shot-to-shot volume consistency of 0.001cm³

- Runner weight of less than 0.25g

- Insert micro-molding equipment

- Complete in-house and on-site service department

- MIS device design and manufacturing engineering assistance

Explore the July 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

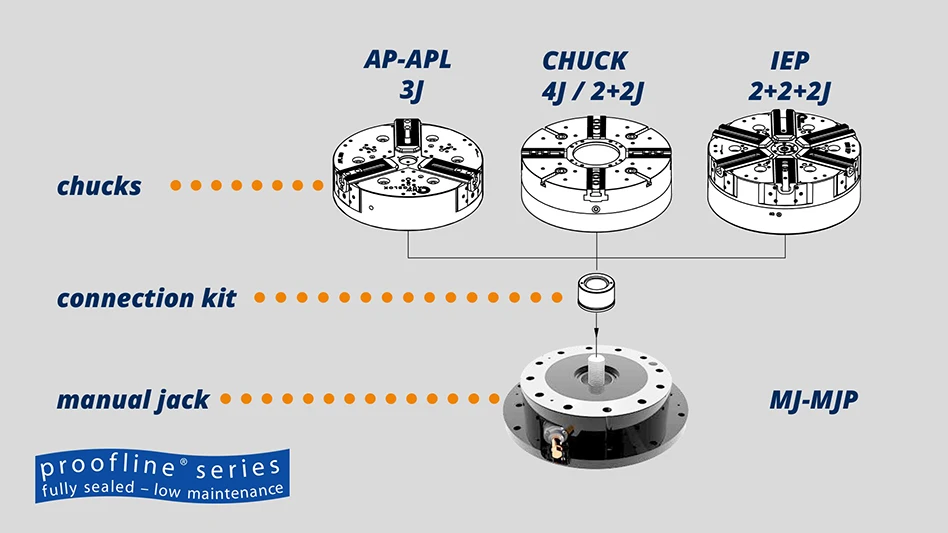

- Workholding Roundtable with SCHUNK, EMUGE FRANKEN USA, and SMW Autoblok

- Canadian company wins ROBOTICS AWARD 2025

- XP Power’s CCR AC-DC power supplies

- Quality Control of Surfaces in the Digital Age

- High precision, productivity in combined punching and shearing systems

- GROB G550T 5-axis mill-turn universal machining center

- Betacom, Siemens launch 5G network platform to accelerate manufacturing innovation

- Starrett’s AVR400 CNC vision system