Software engine increases speeds and feeds.

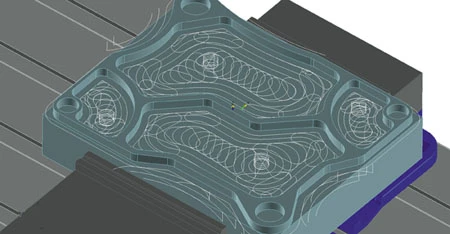

Shops doing medical machining can now precisely control a cutting tool's engagement with workpiece material to run moreaggressive machining parameters that reduce cycle times. The TrueMill toolpath engine within SurfCam software reportedly generates smooth, fluid toolpaths that leverage the motioncontrol capabilities of CNC machine tools.

According to Glenn Coleman, vice president of product design at Surfware, material removal is not only much faster with TrueMill, but also more efficient and with less stress on cutting tools and machines. The engine's toolpaths are free of spikes or sudden changes in tool loads. Thus, shops machine using combinations of parameters such as spindle speed, feedrate, depth of cut, and stepover that would result in part damage or tool breakage with existing toolpath generators.

"One important aspect of TrueMill is its complete independence from the machining hardware, including cutting tools, toolholders, controllers, and machine tools," explains Coleman. "All things being equal, TrueMill toolpaths run faster and deeper than other toolpaths for shorter cycle times and longer tool life."

Surfware Inc.

Westlake Village, Calif.

surfware.com

Circle 201

Explore the July 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module