Solvay

Solvay's Radel PPSU resin helped Legacy Medical Solutions optimize a large-format sterilization tray for surgical instruments. Radel polyphenylsulfone (PPSU) resin’s strength-to-weight ratio, ability to withstand high pH cleaners during repeated sterilization cycles and high-temperature autoclaves were key factors in Legacy Medical Solutions’ decision to utilize the material to improve the design, manufacture and use of the tray.

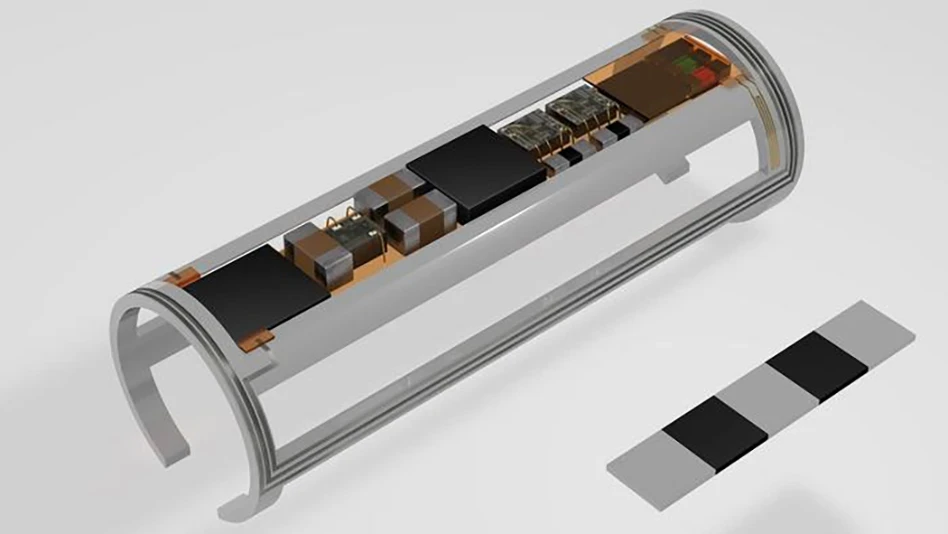

Legacy Medical Solutions’ unique sterilization tray, measuring 23.5" x 15.0" x 5.6" (59.7cm x 38.1cm x 14.2cm) is comprised of a thermoformed Radel PPSU transparent lid and an opaque base tray that secures with a metal clamping system. The transparent lid provides visibility of the tray’s contents for added convenience. The base tray weighs up to 50% lighter than competitive models fashioned with anodized aluminum, a traditional material of choice, and features large drilled holes for effective venting during sterilization. Radel PPSU resin also provides the tray with superior impact strength, flexibility and chemical resistance. Importantly, the material is compatible with various sterilization methods, including autoclaving at 280°F (138°C) for sustained periods of time, demonstrating exceptional toughness and maintaining excellent aesthetics.

“Today’s sterilization trays need to withstand punishing autoclaving protocols with high pH cleaners, through hundreds of sterilization cycles,” says Joel S. Hughes, president of Legacy Medical Solutions. “Anodized aluminum trays can fade quickly after just one sterilization cycle if treated with high pH cleaners, but the trays we make with Radel PPSU retain their fresh appearance thanks to the material’s superior chemical and heat resistance.”

Legacy Medical Solutions also selected Solvay’s Radel PPSU because this high-performance, medical grade polymer supports the design and manufacture of a customizable platform. Through the addition of an innovative bracket, multiple insert plates can be used, and the number of sterilization validations can be reduced. Radel PPSU resin further enables product customization due to its availability in a variety of transparent and opaque colors that can support customer corporate branding efforts.

“Solvay’s commitment to innovative product development is demonstrated through its collaboration and technical support for leaders like Legacy Medical Solutions,” notes Dane Waund, global marketing manager for healthcare at Solvay’s Specialty Polymers global business unit. “With this large-format sterilization tray, Solvay’s Radel PPSU resin is enabling dramatic design improvements, supporting a variety of manufacturing methods, and ensuring superior performance and a longer product life.”

Latest from Today's Medical Developments

- Stretchable, flexible, recyclable – this plastic is fantastic

- Discuss the upcoming year in manufacturing with GIE Media editors

- TDK Ventures invests in ANYbotics

- Our first webinar of 2025 highlights additive manufacturing

- Costa Rica, a global magnet for medical devices

- PhD student helps develop medical device for children with congenital heart defects

- Happy New Year

- Best of 2024: #1 Article – 2024 Forecast