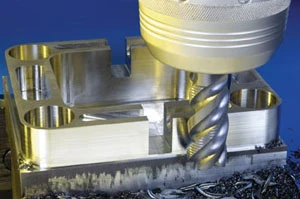

Iscar is introducing a solid carbide endmill family of tools. The FINISHRED's innovative Fast Metal Removal (F.M.R.) design makes it possible to machine both roughing and finishing applications in the same process. Projects that require a roughing and a finishing process can now be accomplished with one tool, in one process. The FINISHRED from Iscar is designed to combine these two tool types, allowing the machinist to complete roughing and finishing operations in one process and eliminating the need for both tools. The EFR B44 FINISHRED endmill features four flutes with 45° helix. There are two serrated flutes designed for roughing and two continuous flutes designed for finishing. In addition, the FINISHRED produces both short and long chips simultaneously, making it applicable for slotting and cavity milling applications. The new endmill is suitable for all types of steel in addition to titanium, inconel, and high temperature alloys.

Iscar Metals, Inc. Arlington, TX iscar.com Booth #E-2317

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries