The mission of Smith+Nephew, a global medical technology company, is replacing defective body parts and improving patients’quality of life. The company employs around 18,000 people in more than 100 countries. With the development and application of innovative technologies, they work diligently to improve the products of three global business divisions: orthopedic reconstruction, modern wound care management, and sports medicine. This commitment to excellent medical solutions is reflected in Smith+Nephew’s new plant in Penang, Malaysia, a part of the orthopedic reconstruction division primarily producing endoprosthetic knee and hip implants.

Optimal surface finishes

“For each of our implants we have specifications that precisely define the required quality of their surface finish,” Jürgen Preiser, senior manufacturing engineer at Smith+Nephew explains.

Preiser is coordinating establishment of the surface finishing manufacturing cells for the knee implants made from cobalt chrome alloys in the Penang plant. For example, the inner surface areas of femur components must have a precisely defined surface roughness to promote optimal integration into the bone. The outer surface areas must have a very smooth, polished surface finish to prevent friction that could cause premature wear. Therefore, some targeted outer surface areas of the femur components must undergo a demanding finishing operation delivering repeatable, consistent results.

Drag finishing

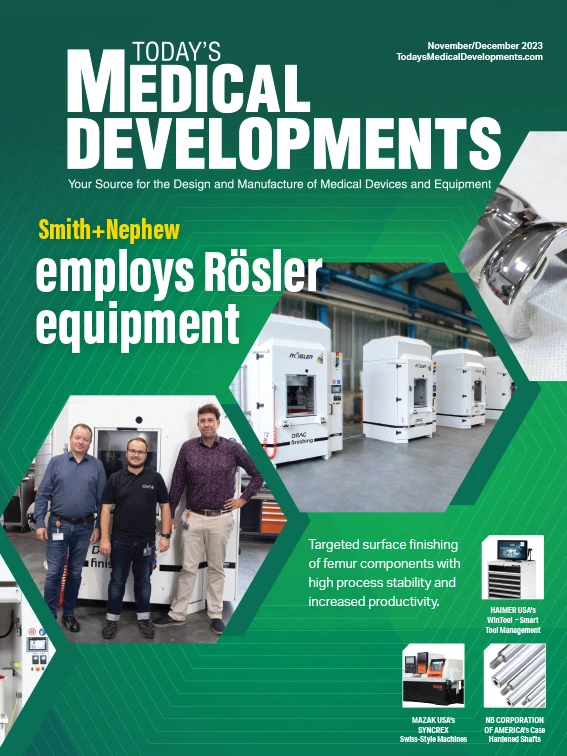

Smith+Nephew usesRösler R 6/1000 SF drag finishers – special mass finishing systems developed for precise, targeted surface finishing of high-value and delicate workpieces with complex shapes. It’s extremely important for femur components not to touch during the surface grinding and polishing operation. Because of this, all process parameters are stored in the PLC control panel, guaranteeing repeatable, consistent results.

“Since our plant in Memphis, Tennessee is using identical finishing processes and machines for the same application, we have plenty of experience and know-how,” Preiser explains. “This facilitated and expedited the approval for the respective equipment and finishing processes. Another point in favor of Rösler was the company’s global presence. Moreover, Rösler develops and produces all its products in-house. This allows the optimal adaptation of equipment and consumables and guarantees a stable source of supply.”

Two cells, three drag finishers

The plant on the Malayan peninsula is equipped with two manufacturing cells, each containing three drag finishers for the process stages: pre-grinding with ceramic media, pre-polishing with plastic media, and dry polishing with a specially prepared organic polishing medium. All drag finishers can run the dry polishing process to prevent any disruptions of the surface finishing operation. Furthermore, four of the six drag finishers can pre-grind, pre-polish, or dry polish.

50% higher workpiece throughput

The drag finishers consist of a processing bowl with 1,000mm diameter and a six rotary spindle carousel. These are equipped with specially designed workpiece fixtures, to which the femur components are mounted. The fixtures’ design allows clamping the workpieces in a position that allows finishing precisely defined surface areas. A redesign of the fixtures now allows increasing the femur components clamped to one fixture from two to three, without jeopardizing the all-around treatment and finishing quality.

“We can process 18 femur components in one single batch compared to only 12 in the past. This increases our throughput by around 50%, a truly remarkable boost of our productivity,” Preiser explains.

During the start phase of the grinding and polishing process the rotating carousel is lowered, causing workpieces attached to the rotating spindles to be immersed into the media contained in the stationary processing bowl. The built-in immersion depth-control system ensures the specified immersion depth for the various workpiece types is precisely maintained. Separate, independently controlled carousel and spindle drives allow the optimal adaptation of the processing intensity to the various femur types.

Guaranteed good results

Maintaining the optimal media fill level in the processing bowl and the optimal media operating mix is extremely important to consistently achieve high finishing qualities. Media level is monitored visually and with special sensors. A message is displayed in the control panel, whenever an action by the operator is needed.

“In addition, to maintain a consistently high finishing quality, we installed a media classification system, consisting primarily of a vibratory screening unit. Once per week we pass the ceramic and plastic media through the screening unit, where all undersized media are discharged from the operating mix,” Preiser notes.

For cleaning and recycling process water from the wet pre-grinding and pre-polishing operations in the two manufacturing cells, Smith+Nephew purchased two fully automatic Z1000 centrifuges.

“The dual centrifuge concept lets us operate two separate process water cycles, one for finishing operations with ceramic and one for the operations with plastic media. Maintaining two separate water cycles helps us prevent all kinds of problems, for example, foaming issues,” Preiser explains.

The control panel of each centrifuge is equipped with the digital process water management system from Rösler Smart Solutions, enabling monitoring, data collection, and evaluation of up to 14 individually selectable process parameters. These include the compound concentration, pH value, and microbiological contamination. The parameter target values and their respective tolerance range are stored in the software, and the actual values are entered for comparison purposes. Whenever one or several parameters are drifting out of the predefined range, the system displays an error message and issues easy-to-understand recommendations allowing a quick return to the specified tolerance range.

“With the digital management system, we control the process water cleaning and recycling operation a lot better. In addition, it helps us with training those employees who know very little or nothing about how to handle the process water,” Preiser comments.

Moreover, recording the parameters throughout a longer time helps identify long-term trends so necessary process water changes can be precisely scheduled with minimal disruption of manufacturing operations. The digital process water management system also significantly reduces consumption of compound and fresh water. And finally, the careful recording of all relevant water parameters represents an excellent tool for documenting the process quality and stability for quality audits and documentation purposes.

“The first two manufacturing cells underwent the mandatory validation phase and the start of full-scale production took place in the spring of 2023. Now we are planning two additional manufacturing cells for the same products and finishing processes,” Preiser concludes.

Rösler

https://www.rosler.com

Explore the November December 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- IMTS 2026 runs Sept. 14-19 at McCormick Place in Chicago, Illinois

- Master Bond’s MasterSil 800Med

- ZEISS celebrates 100 years of advancing innovation in the US

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out