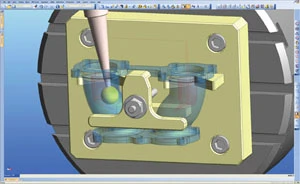

EdgeCAM 10.5 introduces new capability for 4-and 5-Axis simultaneous machining in order to reduce programming times and improve manufacturing efficiency. Surface finish improvements are delivered by tilting the tool to maintain the optimal tool-to-part contact point at all times and provide improved access to undercuts and deep pockets. EdgeCAM provides strategies for ‘Swarf' cutting of variable taper walls, sophisticated multi-surface finishing with automatic collision avoidance, machining of impeller-type components, and de-flashing of plastic molded components. The new software also provides improvements in visualization of the machining process with simulation for mills, lathes, and mill/turn machines, allowing the user to avoid collisions and ensure safe operation. Machining times can be shortened in deep cavities with EdgeCAM 10.5's plunge roughing strategy. The tool repeatedly feeds down the Z-Axis with the main load occurring in the tool axis direction, reducing tool deflection, and resulting in increased tool stability and maintained feeds and speeds.

Pathtrace Systems Inc. Southfield, MI edgecam.com Booth #D-3110

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module

- Humanoid robots to become the next US-China battleground

- Air Turbine Technology’s Air Turbine Spindles 601 Series

- Copper nanoparticles could reduce infection risk of implanted medical device

- Renishaw's TEMPUS technology, RenAM 500 metal AM system

- #52 - Manufacturing Matters - Fall 2024 Aerospace Industry Outlook with Richard Aboulafia

- Tariffs threaten small business growth, increase costs across industries