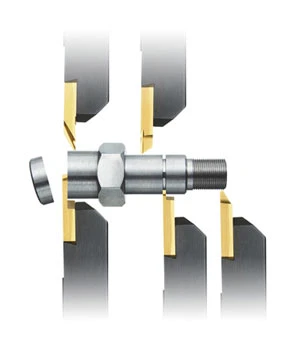

The CoroCut XS is an innovative product line from Sandvik Coromant designed to produce precision-turned components with diameters as small as 1mm. The tool provides the accuracy and reliability needed for small part manufacturers specializing in small medical components.

CoroCut XS allows for productivity gains in high volume production. XS Inserts are precision ground to contain extremely sharp edges, ensuring the tightest possible tolerances in external machining operations, such as grooving, threading, parting and turning. The CoroCut XS has a grooving width of just 0.5mm and a parting width of only 0.7mm.

The CoroCut XS provides a flexible solution; all inserts are compatible with the same tool holder for all operations. The design also allows the insert screw to be reached from either side of the tool holder, offering easy access when indexing the insert.

Tool Information:

Nose radius: 0.05mm

Widths: 0.5mm, 1mm, 1.5mm, 2mm and 2.5mm

Hand: Available in left and right handed versions.

Grades: 1025

Geometries: MAG (chip breaker) and MAC-T (flat)

Insert tolerances: Repeatability, +/- 0.025mm

Holders: 10mm, 12mm and 16mm (and inch equivalent) are available in left and right handed versions.

Features:

The CoroCut XS grooving geometry is designed for high precision grooves with a width tolerance of +/- 0.025mm, with small grove radius guaranteed no larger than 0.05mm. The insert has a true flat cutting edge.

Practical Hints from Sandvik:

1. When the groove is wider than it is deep, it is beneficial to plunge turn and when the groove is deeper than it is wide, it is beneficial to use multiple grooving.

2. Too low of a cutting speed will result in inadequate tool life; to increase tool life it is recommended to follow cutting speed recommendations.

Explore the June 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- HERMES AWARD 2025 – Jury nominates three tech innovations

- Vision Engineering’s EVO Cam HALO

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software

- FANUC America launches new robot tutorial website for all

- Murata Machinery USA’s MT1065EX twin-spindle, CNC turning center

- #40 - Lunch & Learn with Fagor Automation

- Kistler offers service for piezoelectric force sensors and measuring chains

- Creaform’s Pro version of Scan-to-CAD Application Module