In the intricate world of medical device development, risk management often conjures images of tedious paperwork and regulatory hurdles. However, a paradigm shift is underway. ISO 14971, the internationally recognized standard for medical device risk management, is emerging not just as a compliance tool, but as a powerful catalyst for innovation and improved patient safety.

From compliance to competitive edge

ISO 14971 offers a structured approach to systematically identify, assess, and control risks associated with medical devices. By proactively addressing potential hazards throughout the product life cycle, companies can move beyond mere compliance and genuinely gain a competitive edge.

The standard fosters innovation by encouraging a deep understanding of the device’s intended use; its potential interactions with users, patients, and the environment; and the possible harm that could arise. This knowledge empowers design and engineering teams to develop creative solutions that mitigate risks, enhance safety features, and improve the overall user experience.

Empowering engineers: Informed decision-making

ISO 14971 equips engineers with a robust framework for making informed design decisions. By clearly defining risk acceptability criteria and providing tools for risk analysis and evaluation, the standard guides engineers in prioritizing safety and performance throughout the development process.

In addition, the standard emphasizes the importance of considering clinical and engineering risks. While clinical risks primarily focus on patient safety, engineering risks encompass factors such as device reliability, manufacturability, and serviceability. A comprehensive understanding of both risks enables engineers to optimize designs, identify potential failure modes, and implement effective control measures. For example, a particular function of the device may result in a high risk. Though it’s difficult to impact the severity of the device function, the occurrence could be reduced by taking another pathway. The challenge of creating a new design approach may result in the discovery of a new insight and create a better overall solution.

Usability engineering, as outlined in IEC 62366-1, plays a crucial role in risk management. By considering the device’s interaction with users, including healthcare professionals and patients, engineers can identify and address potential use errors, enhancing the overall user experience and further improving patient safety. Making products more accessible and more intuitive for users to interact with leads to higher user satisfaction, increased efficiency, and fewer errors during use. When products are designed with the user in mind, they become more enjoyable and accessible, which can lead to better adoption rates and customer loyalty.

Furthermore, the interaction and interdependence of risks with the engineering requirements are vital to ensuring the safety, functionality, and reliability of a system. Engineering requirements define the goals and parameters of a project, while risk management identifies potential threats that could hinder achieving those goals. By integrating risk analysis with engineering requirements, teams can prioritize critical design aspects, address potential failures early, and ensure the system meets performance standards and safety expectations. This proactive approach reduces costly revisions and prevents failures, ultimately delivering a product that’s both effective and resilient in real-world conditions.

Clinical risks to the patient can often – understandably – be an engineer’s focus, but this standard asks you tto consider the wider ecosystem in which the device will come into contact. With almost every device there are broader user risks, encompassing the nurses, the doctors, care workers, home help, or whoever else might be supporting the patient.

A simple example is a syringe with a needle on it. When it was first developed, it solved the problem of getting medicine into the patient. But it has subsequently been re-designed and re-engineered multiple times to protect the user from being accidentally pricked – nurses, doctors, care practitioners, or even the patient themselves.

What ISO 14971 encourages is a broader scope, and a broader scope can save millions in future redevelopment costs.

Life cycle integration: Ensuring safety and effectiveness

ISO 14971 advocates for the integration of risk management into every phase of the product life cycle, from concept to post-market surveillance. This proactive approach ensures potential risks are identified and addressed early in the development process, reducing the likelihood of costly design changes or product recalls later.

Life cycle integration facilitates continuous improvement. By actively monitoring and evaluating device performance in the real world, companies can gather valuable feedback and identify emerging risks. This information can be used to refine risk control measures, update product labeling, and inform future product development efforts – ensuring the device remains safe and effective throughout its lifespan.

Crucially, the standard also recognizes the risk landscape can evolve over time. New technologies, changes in clinical practice, or the emergence of unforeseen hazards can necessitate a re-evaluation of existing risk control measures. By embracing a life cycle approach, companies can adapt to these changes and proactively manage risks, even for devices that have been on the market for years.

Beyond documentation: Strategic value and knowledge transfer

Like many other standards, this requires supporting paperwork. But while documentation is a critical component of ISO 14971 compliance, it shouldn’t be viewed solely as a regulatory burden. Robust documentation provides a valuable record of the risk management process, demonstrating a company’s commitment to safety and efficacy. This can streamline regulatory approvals and instill confidence in healthcare professionals and patients.

Furthermore, documentation serves as a powerful tool for knowledge transfer, continuous improvement, and future innovation. By capturing design decisions over time, risk assessments, and lessons learned, companies can build a repository of valuable information that can inform future product development efforts and facilitate effective communication across teams and departments.

Overcoming challenges: Practical implementation

Implementing ISO 14971 can be challenging, particularly for smaller companies or those new to the medical device industry. However, with careful planning and a focus on practicality, these challenges can be effectively addressed.

- Mindset: Some engineers may view ISO 14971 compliance as a bureaucratic burden that hinders innovation and slows product development. This perception can lead to resistance and a lack of engagement with the risk management process, so it’s important to approach the process positively.

- Training and resource allocation: Invest in comprehensive training for engineers and other team members involved in the risk management process. Start with fundamental concepts such as design failure modes and effects analysis (DFMEA) and build upon that foundation. Allocate resources effectively, ensuring teams have the time and expertise needed to conduct thorough risk assessments and implement appropriate control measures.

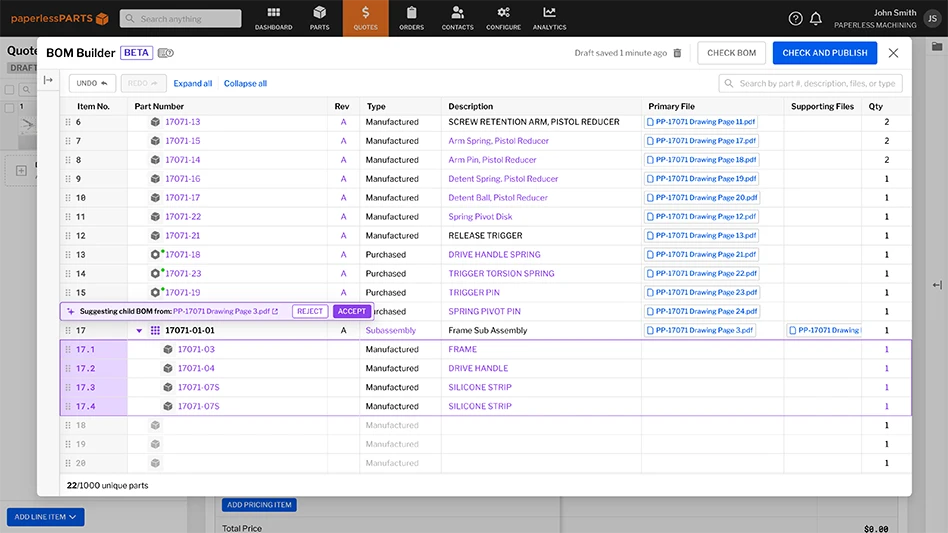

- Tool selection: Choose risk management tools and methodologies that match the complexity of your device. While basic tools such as Microsoft Word and Excel may suffice for simpler devices, more complex products may require dedicated software applications to manage the sheer volume of data and facilitate collaboration. Today, there are some outstanding requirements and risk management software tools available for managing both the interactions between engineering requirements and risks (e.g. Greenlight Guru, PTC Arena, Siemens Polarion, Aligned, etc).

- Clear and actionable procedures: Yes, the standard is written in technical language, but that doesn’t mean your plan has to be. Develop clear, concise, and actionable steps that guide engineers through the risk management process. Avoid overly verbose or complex language that can create confusion and hinder implementation. Distill it into a to-do list.

- Focus on the essentials: Don’t overcomplicate the process or create unnecessary paperwork. Focus on the core principles of ISO 14971 and tailor your approach to the specific needs of your product and its intended use. Not everything will be relevant to you.

- Seek expert guidance: If needed, don’t hesitate to seek guidance from experienced consultants or regulatory experts who can provide valuable insights and support throughout the implementation process.

Conclusion

We’ve all seen new technologies fail. Risk management and usability engineering are crucial to the adoption of new technologies. If technology is too complex or confusing, users may resist adopting it, regardless of its potential benefit.

ISO 14971 is more than just a regulatory requirement. It’s a powerful tool to drive innovation, improve patient safety, and enhance the overall user experience. By embracing a proactive and life cycle-oriented approach to risk management, medical device companies can develop safer, more effective products that truly benefit patients and contribute to the advancement of healthcare. The standardized process provided by ISO 14971 helps create a level playing field for companies of all sizes. This enables startups and small and medium-sized enterprises (SMEs) to compete by developing innovative solutions that address unmet clinical needs or improve existing technologies.

Archetype Medtech

https://www.archetype-medtech.com/

Explore the January/February 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- A 30-year journey through CAM: Insights on simulation technology

- Behringer Saws’ HBE663A Dynamic horizontal bandsaw

- North America's supply chains face sharp decline due to tariffs

- Experience precision: GF Machining Solutions' CUT F Series wire EDM

- Mastering high-temp alloys with Kennametal Inc.

- Integer expands operations in Salem, creating 83 jobs

- Siemens unveils new Teamcenter X: Revolutionizing SaaS PLM for all manufacturers

- 3 Questions with an Expert with Allied Machine & Engineering