The precision-ground, replaceable aluminum top plate for modular Vac-Vise vacuum chuck systems works in conjunction with the 2L Vac-Vise modular vacuum chucks. It covers the surface of the vacuum chuck to allow drilling through and milling around the periphery of workpieces without damaging the surface of the vacuum chuck. The hole pattern of the replaceable top plate is identical to the Vac-Vise vacuum chuck for quick setup and consistent workpiece placement.

The replaceable aluminum top plate fastens securely to the 2L vacuum chuck with the included brass screws, which can be machined without causing damage to the standard cutting tools being used to machine the workpiece.

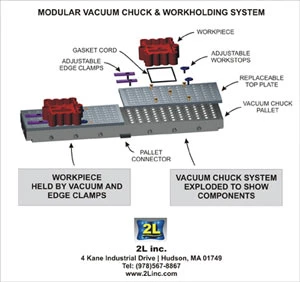

2L Vac-Vise vacuum chucks offer a comprehensive system for vacuum workholding of a variety of parts. The modular vacuum chucks and accessories, such as the replaceable aluminum top plate, adjustable workstops, and edge clamps allow for easy prototyping and fast and repeatable setup for production environments.

Four pre-configured vacuum chuck kits are available for ease of ordering:

- Single pallet vacuum chuck kit(pallet size of 8" x 12").

- Two pallet vacuum chuck kit (combined pallet size of 16" x 12", or 8" x 24").

- Three pallet vacuum chuck kit (combined pallet size of 8" x 36" or 24" x 12").

- Four pallet vacuum chuck kit achieves a larger pallet workholding area (combined pallet area of 16" x 24").

Complete System

The Vac-Vise vacuum chuck workholding system allows for easy prototyping of workpieces and eliminates the need to create custom fixtures. It can be used as a vacuum chuck for workholding or as a pallet workholding system using the adjustable workstops and edge clamps. Numbered locations allow for quick setup and consistent workpiece placement. Users of the modular vacuum chuck can use one Vac-Vise vacuum chuck pallet, or combine several Vac-Vise vacuum chuck pallets to increase the workholding area.

The low profile adjustable edge clamps and workstops reduce setup time, eliminating the need for custom fixtures, and allowing for quick and flexible setup for prototypes. Each Vac-Vise pallet has 77 threaded ¼-20 holes with accurate 1" spacing for clamps to enable accurate spacing, as well as 29 vacuum/clamp holes.

Repeatable setup for high production is achieved through repeatable workpiece positioning between pallets. Load one Vac-Vise off-line while another is being machined. The Vise stop-pin locates the pallet in the milling vise and the threaded hole locations are labeled to allow documenting setups. Quick vacuum gasket cord placement allows easy workpiece size changes – where side and end workstops locate the workpiece consistently.

The modular vacuum chuck and workholding can be held in a standard milling vise or attach a Vise-Block for vise openings as small as 5". The steel vise-block allows holding of aluminum, plastic and thin workpieces on a magnetic chuck for surface grinders.

Explore the May 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3