Reishaw

Renishaw has partnered with Davis Technical College (Davis Tech), a public technical college in Kaysville, Utah, to provide students with access to the latest in measurement technologies. CNC machining students now have on-site access to coordinate measuring machines (CMMs) and other Renishaw equipment that is helping them to take fast, precise measurements of components.

For over 30 years, Davis Tech has been training and enhancing the lives of its thousands of students as they prepare for a career in the industrial workforce. Through its partnerships, Davis Tech engages industry, educational, and community members to provide shared opportunities for all. Courses found within the program include automation and robotics, CNC machining and manufacturing technology. The range of educational opportunities offered are designed to effectively train the workforce using cutting-edge industry methods.

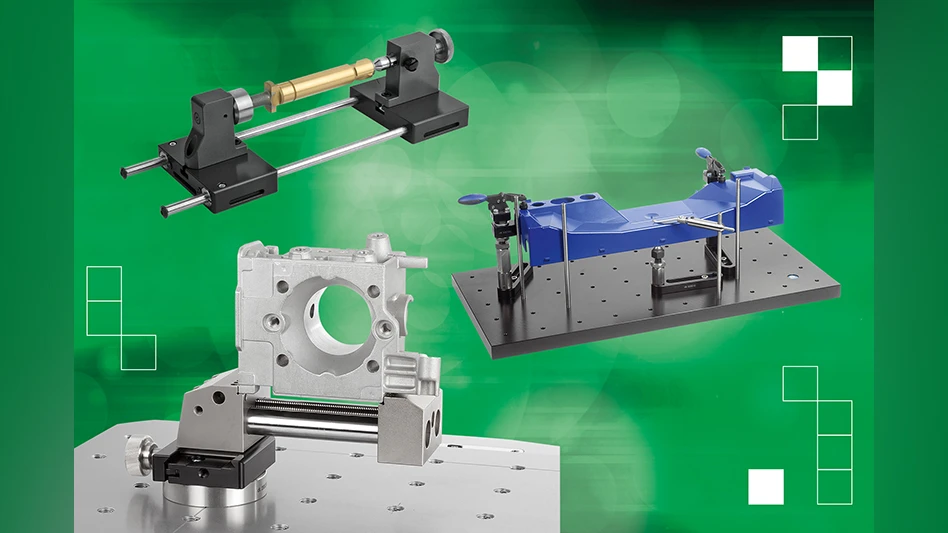

Renishaw’s U.S. subsidiary has committed its expertise to the program as well as a host of the company’s advanced manufacturing equipment. Renishaw Inc’s Steven Fisher and Devon King are program liaisons and two Renishaw engineers are also always available for demo support and assistance. Students are learning part measurement on Renishaw Equator gaging systems, part variation using a 5-axis REVO CMM measuring system, conducting machine health checks using the QC20-W wireless ball bar system, and learning how to set up machines with Renishaw machine tool probes and styli.

“We see the importance of addressing the manufacturing skills gap and this is a natural way for us to get involved,” says Fisher, district sales manager, Renishaw Inc. “We consider this a further advancement of similar programs across the United States.”

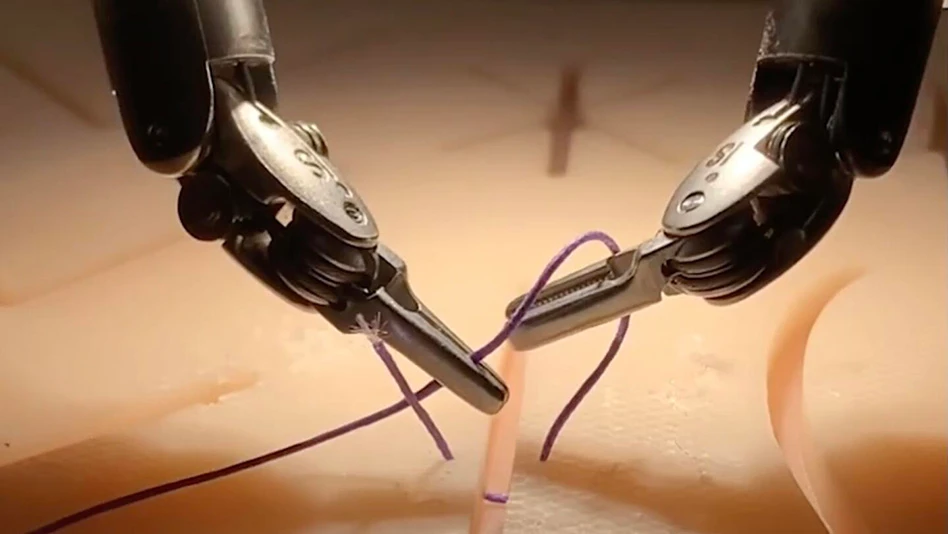

Students will design, build, test, and troubleshoot automated technology, which is directly tied to industrial processes. The program offers students the opportunity to apply hands-on learning to prepare them to meet industry needs in their respective fields including automation and solar energy systems, as well as other forms of alternative energy.

Students enrolled in the CNC Machining program also use industry standard tools, equipment, and procedures, the same as entry-level machinists. Students will study blueprint reading, sketching, part design, CNC operation and CNC programming. The program offers training in lathe, mill, and drill press, as well as related skills in mathematics, use of precision measuring tools and mechanical inspection methods to produce precision parts with extremely close tolerances.

Latest from Today's Medical Developments

- Viant expands medical device solutions

- MIDACO’s automatic 4-pallet changer with trunnion system

- Breaking Free of the Additive Manufacturing Echo Chamber

- Boston Scientific to Acquire Cortex

- Don’t miss this month’s Manufacturing Lunch + Learn!

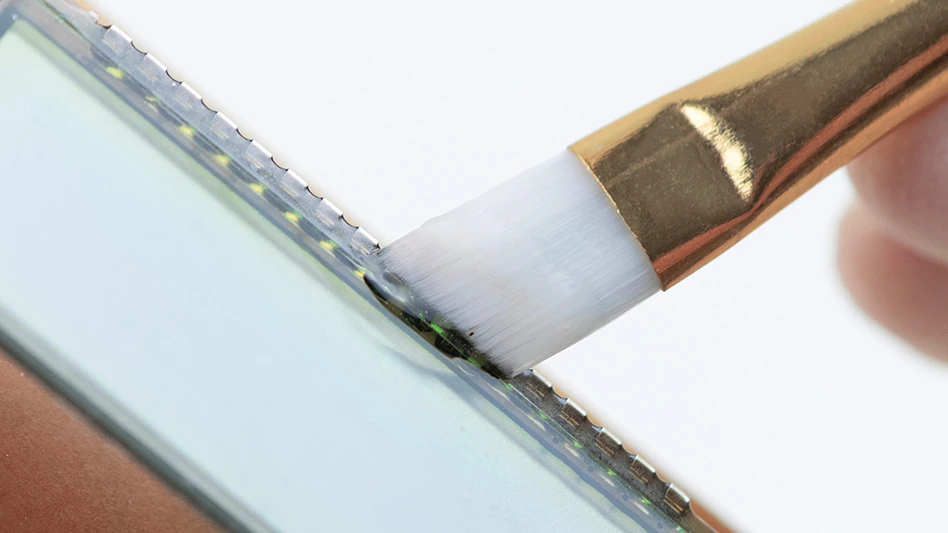

- Coating could make medical devices safer for patients

- How robots and cobots can work for you

- Renishaw receives Industry Partner Award