Companies that wish to compete in any aspect of medical device manufacturing have to be fast and flexible. The speed requirement results from the seemingly countless trial, evaluation and approval steps required to bring a medical device to market. Long lead times between steps are product killers and can not be tolerated. The flexibility imperative is a reflection of the intensely competitive nature of this marketplace.

Orchid Design, a contract engineering, prototyping and product development firm serving the medical device market, understands these requirements very well. When this shop became part of the multi-divisional Orchid Orthopedics Solutions LLC, one of the first orders of business was to install manufacturing systems (a Swiss turning, 5-axis mill and 4-axis wire EDM) that mirror the equipment used at the corporation's other production machining divisions.

As a result, when Orchid Design transfers a job from prototyping or short run manufacturing, to one of the corporation's production shops, a completely validated part and compatible manufacturing process goes along with it. Production manufacturing can begin immediately with little or no process tweaking needed.

For Orchid Design, that is the end of an intense race that typically begins with someone – a doctor, a manager from a small start-up company, or a designer from a major medical device manufacturer – bringing them an idea. This event triggers a whole series of steps than may include concept development, product engineering, prototyping, design modifications based on cadaver lab tests, and small run contract manufacturing.

Ron Callahan, prototype shop manager for Orchid Design explains, "We don't do the standard 12 to 14 week lead time. Most of our parts are delivered in two to three weeks. However, it is not unusual for a customer to order a design in the morning and expect us to have parts for him at the end of the day. Our CAM system allows us to do that."

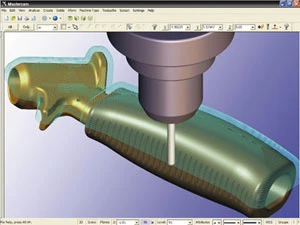

Orchid Design uses Mastercam X CAD/CAM software to rapidly transform medical designs generated in Solid- Works or Pro/Engineer into precise CNC toolpaths for its CNC manufacturing equipment. But that is only half the story. Once the toolpaths have been created, the company also uses the CAD capabilities of Mastercam to design workholding fixtures that allow the equipment to remove the maximum amount of material with the fewest possible setups.

"We run the toolpath around the model with the fixture in place to make sure we don't hit the fixture and that the fixture will clear all of our axes," Callahan says. That is just one of dozens of little tricks he has learned to get parts up and running efficiently on the company's CNC equipment the first time, without backtracking.

Medical Jewelry

A high percentage of the CNC work done at Orchid Design is micromachining. These are very tight tolerance parts, and they have to be aesthetically appealing because eye appeal is a very important aspect of medical device marketing. "We call it medical jewelry," Callahan says. "Currently we are working on parts that are all smaller than my pinky nail, and are ±0.0005" tolerance made out of titanium with 5-axis helicals, and on the opposite sides there's surfacing and orientations to drive features."

Orchid Design is using 0.015" diameter endmills to finish these little parts on its 5-axis mill. That tool would be about the diameter of four human hairs. Mastercam is especially helpful here because it automatically calculates the volume of material removal and adjusts stepovers and feedrates accordingly to manage the chip load and avoid tool breakage.

"I would love to show you those parts, but I can't." Callahan says.

CAM Compression

What he could show us, with permission from his customer, SpineFrontier, Inc., was an intricate handle, part of the mating assembly for a surgical instrument known as an "obturator." It looks something like a four-leaf clover with a lot of compound angles and through-holes. The handle, complete with thumb grips, is surfaced to provide the surgeon a high degree of comfort and control. There is also a bore for an O-ring, radial slots for the mating gripper, a couple of drilled holes for pinning a trigger, and a large hole through the back of the handle for weight reduction.

Toolpaths for the handle were created in Mastercam in less than half a working day and they were manufactured the next day. To keep this project moving to meet a tight deadline, Callahan used a number of powerful time compression features of the CAM software:

Concurrent Fixture Design. Orchid Design had to manufacture a couple custom fixtures to make this part. "The CAD/CAM nature of the software is a huge help here," Callahan explains, "because I can orient the part to my needs for machining then build my fixture around it. This is something I do all the time."

The handle is surfaced to provide the surgeon a high degree of comfort and control.

Level Manager. One of the tools Callahan uses to program the part efficiently was the Mastercam Level Manager. It allows the CAD programmer to put multiple views of the part – top, side, isometric, etc. – on different levels so that he can quickly flip through the levels and program from different views in whatever order seems to be most expedient. For example, Callahan designed the fixtures in one level and then laid the part over it in other levels to make sure they lined up correctly. Then, Mastercam merged all the levels together to create one seamless CNC program.

Surfacing. The CAM software has the ability to automatically generate contoured toolpaths based on an imported surface model of the part. Only minor tweaking is required, if any, to make sure an appropriate amount of material has been removed from tight spots.

Toolpaths for this handle were created in Mastercam in less than half a working day.

Left-Over Surfacing. For this part, Callahan uses a technique known as "leftover surfacing." He "told" Mastercam that he would be using four tools to make this part on the 5-axis mill – a ½" flat endmill, and three ball endmills: 3/8", ¼" and 1/8", respectively. After creating the toolpaths for roughing the surfaces, the software automatically generates paths for the tools that follow based on the amount of material that the previous tool has been programmed to remove. This approach is a tremendous time-saver.

Backplot and Verify. These two software features confirm that the part can be made without crashing the tool, and that neither too much nor too little material will be removed from any area of the part. Backplot confirms the safety of the toolpaths by rapidly playing back an animation of the cutting sequences. Verify provides a color graphic representation of the part with color coding that visually indicates excessive or inadequate material removal.

A part that took a full eight-hour day to manufacture on the 5-axis mill was programmed in less than half that time. The SpineFrontier Opturator Dilator moved quickly through field trials, engineering revisions and into the marketplace. In the meantime, Orchid Design has employed its portfolio on CAM compression programming techniques over and over again to speed a steady flow of projects along similar paths.

Explore the October 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Machine learning framework enhances precision, efficiency in metal 3D printing

- SkillMill – 60-year-old milling machine with digital twin

- Lumetrics’ OptiGauge II EMS

- EMI completes installation of 128-axis CNC turning & milling machine

- Ottobock invests in innovative technologies from MIT start-ups

- Air Turbine Technology's high-speed live tools for Swiss Lathes

- Sandvik announces several software acquisitions

- Dart Controls’s EZ VFD, variable frequency drives